Working with the experts to establish best solutions

Have questions or need a quote?

Get in touch with the team today.

Working with the experts to establish best solutions

The Customer is a World leader in the manufacturer of wood fibre insulation board. The production techniques employed have been developed overtime and are unique to the business. The principals are similar to plywood production, but there are unique techniques employed in manipulating the fibre to create the correct characteristics.

A well-established process, so not exclusive in this case, is the employment of hot ponds. The objective is to season the timber and make it suitably workable to facilitate conversion. The process employs a series of chain strands to carry the product through water tanks.

The original chain selection was a US standard welded steel chain according to B29-16. A product well known to John King Chains through their US manufacturing plant in Birmingham Alabama. The chain is of a robust and simple construction with a bush circumferentially welded to the cranked link plates of the chain and chain bearing pin with a substantial hot rivets for maximum tensile strength and impact resistance. John King Chains have developed material and heat treatment standards which ensure that the performance of their chain surpasses all others the detail.

We were not selected for OEM supply. The consequence of commercial advantage overriding quality and technical considerations. The original chain installed worked for a period of time before developing substantial operational problems. The chain over time became solid with free movement being almost totally impaired, leading to failure.

The customer called for John King Chains to assist in finding a solution. Site inspection revealed a high degree of contamination in water contained in the tanks.

Samples were taken and the water was subsequently analysed by a test laboratory. Clearly the water is polluted to a high degree, but the material content although diverse was found to fairly innocuous and not particularly high in individual contaminants. It was of an acidic nature , but not at a level where corrosion resistant materials were recommended.

1

2

It was clear the polluted water is coating the chain (p1) and entering the critical clearances between pin and bush and inner and outer plate where it had solidified. The level of contamination could be seen in the debris stripped from the chain and deposited in the return U rail (p2). Resultant seizure has proven to be profound. The cycle of emersion and subsequent drying may have proven to be more dramatic during warm summer months but this is conjecture.

John King’s proposal

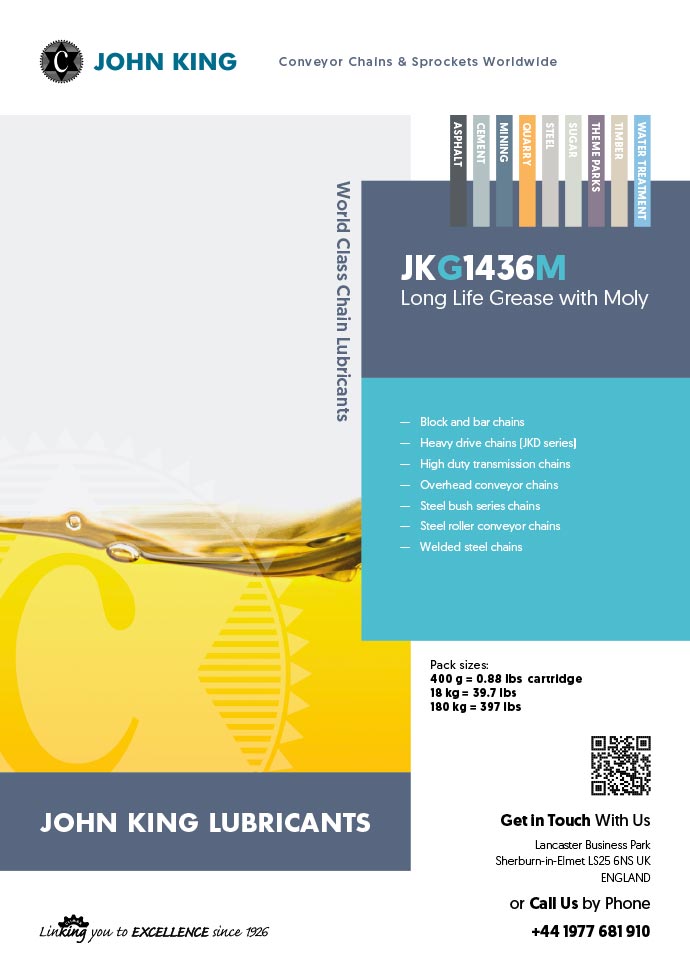

It was considered that the original selection was legitimate. The oversight was in considering the ongoing impact of cyclic emersion into heavily contaminated water and subsequent drying on the return strand. It was the clear opinion that to increase clearances within the two areas between pin and bush and inner and outer link plates would have a positive impact. To achieve this the chain pitch was adjusted so that the running pitch and the gearing relationship between chain and sprockets was maintained. Oil ways were introduced to allow for pre lubrication and periodical ongoing lubrication during service. The lubrication chosen was from the John King range of chain oils and greases type JKO1437M. This revolutionary chain oil offered all the best qualities to work effectively in a wet and hostile environment. The Hybrid welded steel chain supplied proved to be highly successful and the problem was overcome with long term trouble free running the outcome.

A pleasure to behold – John King Chains operating successfully.

“We asked John King chains to help us and they provided a solution. We were pleased to work with a business that were able to establish the nature of the problem and deliver a permanent solution“

The Chief Engineer