Acetal Case Chains

Have questions or need a quote?

Get in touch with the team today.

Link Materials

Standard links are moulded from quality acetal engineering plastic offering optimum mechanical properties in materials handling.

The material offers a unique combination of properties, high tensile strength, excellent dynamic fatigue strength, unique resilience and practical impact strength with a low co-efficiency of friction. (0.15 against metals compared to 0.8 for steel/steel).

In operation chains are quiet, rugged and virtually maintenance free (no need for lubrication) light in weight and low on energy requirements. They offer maximum hygiene advantage and good chemical resistance with minimal moisture absorption. The material exhibits excellent resistance to wear.

Recommended temperature range: -40°C to +90°C (-40°F to +194°F).

Engineering plastics are offered in two standards

PM

Acetal copolymer with self lubricating components. Colour: White, grey and blue.

LF

Acetal copolymer with improved self-lubricating quality. Colour: Brown.

In addition special grades can also be employed including glass reinforced polypropylene and polyurethane and in addition antistatic materials, but special considerations relating to application and production batches are necessary.

Pin Material

Standard pin material employed is from austenitic stainless steel grade AISI 304. (18/8 Cr Ni) offering a high degree of corrosion resistance, high hardness and strength. Ferritic stainless steel can be offered if metal detection is necessary or standard steels with electrolytic zinc plating.

Snap in pin (S)

Standard pin

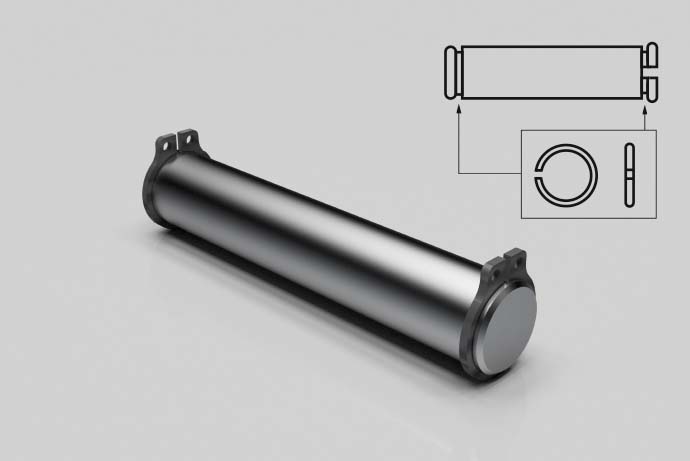

Circlip pin (C)

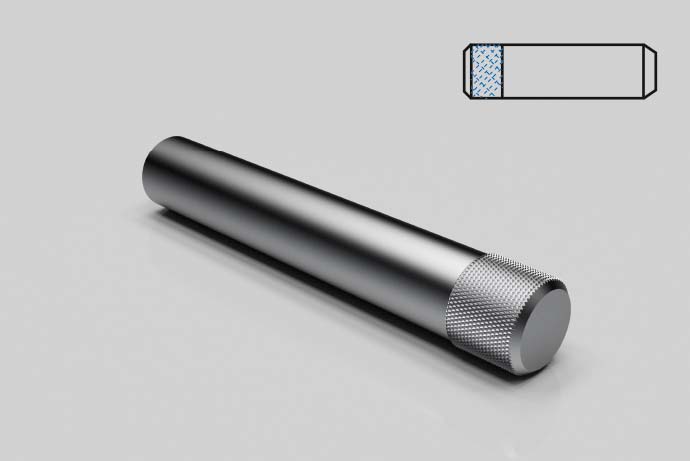

Knurled pin (K)

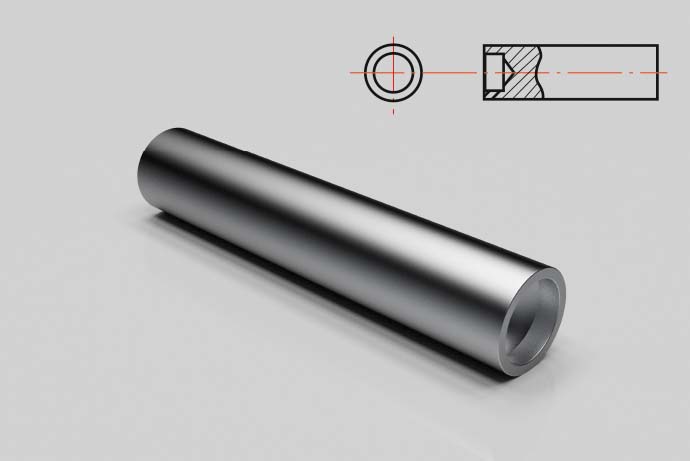

Rivet pin (R)

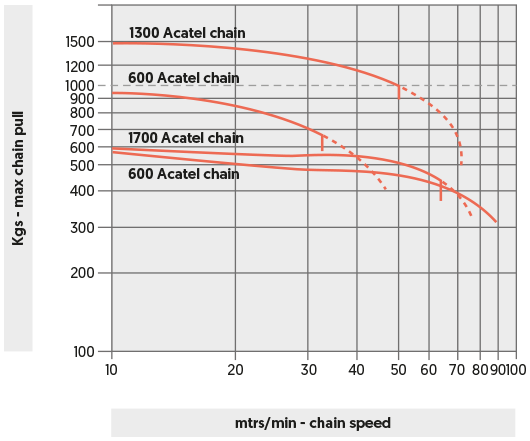

Heavy Duty Chains

To calculate chain pull for conveyors with bends use the following table.

PM600 and PM1300 chain

| Turn Angle degrees | 30 | 45 | 90 | 180 |

|---|---|---|---|---|

| Tf | 1.2 | 1.4 | 1.5 | 2.0 |

Multiply Tf by no. of bends in conveyor length.

Curves should be as far away from head shaft as possible.

When using 1700 chains with turnwheels, calculate as for straight conveyor and multiply result by 1.12n when n = no. of turns.