DAB Slide Valves

Have questions or need a quote?

Get in touch with the team today.

Get in Touch

Ensuring good shut-off and control of your material flow, whether for operational use or for maintenance purposes.

- Construction: Robustly constructed for light, medium or heavy- duty applications.

- Controls: Variety of controls, working to your preference; pneumatic, push/pull, handwheel, motorised, hydraulic.

- Material: Designed to suit the specific environment; Mild steel, stainless steel or composite specials.

- Finish: Aesthetically pleasing finishes to suit the environment; Powder coated/wet painted, natural, bead blast, polished or custom.

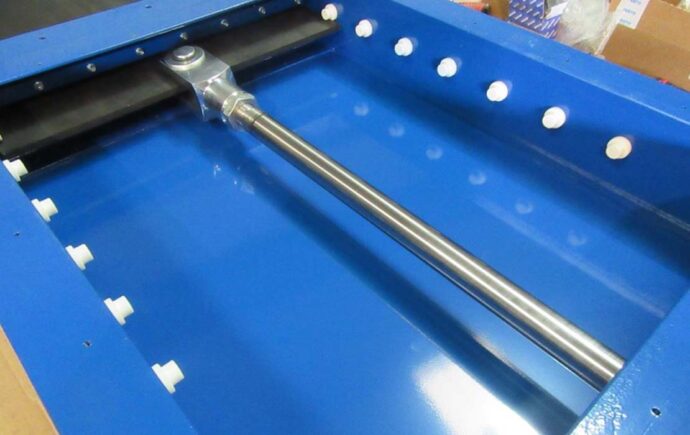

- Plate Seal: Gland or DRF designs with appropriate packing to suit the application.

- Short-Stop: Innovative ‘slide plate short-stop’ to ensure material build up is avoided.

- Slide Plate: Designed to suit your application; square or knife edged.

- Support studs: These are from low friction PETP, mild steel or stainless steel, shouldered to control the slide plate and round to give point contact and allow the material to be swept away and so avoid build up.

- Inlets: Designed around your system directives; Square, round, or rectangular.

- Outlets: Designed around your system directives; Square, round, or rectangular with optional transition piece to round flange or stub.

- Bespoke: Customised to your design & construction for the specific application.

- Typical Duties: Bin, hopper and silo isolation, screw feeder & conveyor shut-off, in-flight catchments & weighing applications.

- Deflectors: Bespoke to your requirement. Vertical as standard, with no obstruction, hang-up or wear areas exposed to the product flow or inclined where a common inlet and outlet size are essential.

- Safety: Available in ATEX, for added safety in applications that offer potential dusty hazardous environments.