Typical dimensions and capacities

Have questions or need a quote?

Get in touch with the team today.

Machine selection is based on long experience of the nature of the material to be conveyed which influences casing size, chain configuration and speed. Simple machines handling free flowing product will accept a higher speed and resultant throughput as compared to similar capacity machines with bends handling sticky and or abrasive products.

For guidance purposes only the tables provide outline machine dimensions ad typical maximum duties for two products Grain and Coal with differing handling characteristics.

For specific requirements John King technical will be pleased to assist.

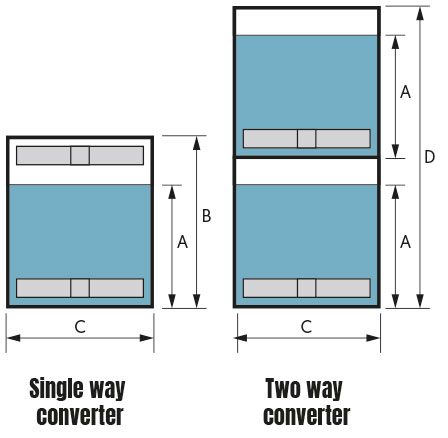

BulkMaster Conveyors

|

MACHINE SIZE |

A |

B |

C |

D |

|

200 |

200 |

375 |

200 |

495 |

|

250 |

248 |

375 |

250 |

543 |

|

315 |

288 |

414 |

315 |

624 |

|

400/250 |

248 |

375 |

400 |

543 |

|

400/315 |

288 |

414 |

400 |

624 |

|

400 |

380 |

534 |

400 |

811 |

|

500/250 |

248 |

375 |

500 |

543 |

|

500/400 |

380 |

534 |

500 |

811 |

|

500 |

480 |

606 |

500 |

1007 |

|

630/400 |

376 |

536 |

630 |

813 |

|

630/500 |

476 |

606 |

630 |

1007 |

|

800/500 |

476 |

606 |

800 |

1007 |

|

1000/500 |

476 |

606 |

1000 |

1007 |

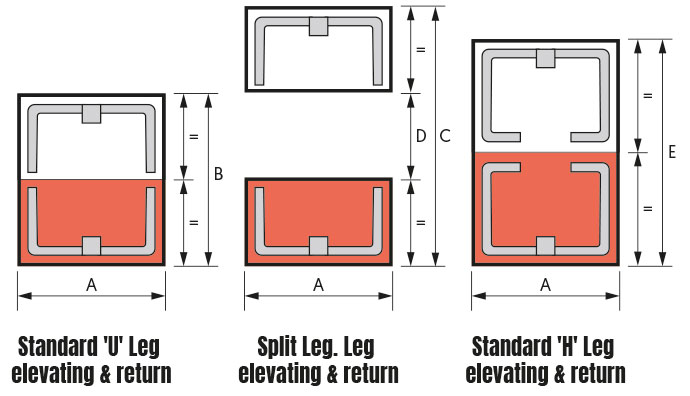

BulkMaster Elevators

|

MACHINE SIZE |

A |

B |

C |

D |

E |

|

200 |

200 |

273 |

835 |

555 |

413 |

|

250 |

250 |

323 |

970 |

640 |

513 |

|

315 |

315 |

363 |

1060 |

690 |

643 |

|

355 |

355 |

415 |

1160 |

740 |

725 |

|

400 |

400 |

475 |

1310 |

830 |

815 |

|

500 |

500 |

637 |

1582 |

938 |

1017 |