King BulkMaster Elevating

Have questions or need a quote?

Get in touch with the team today.

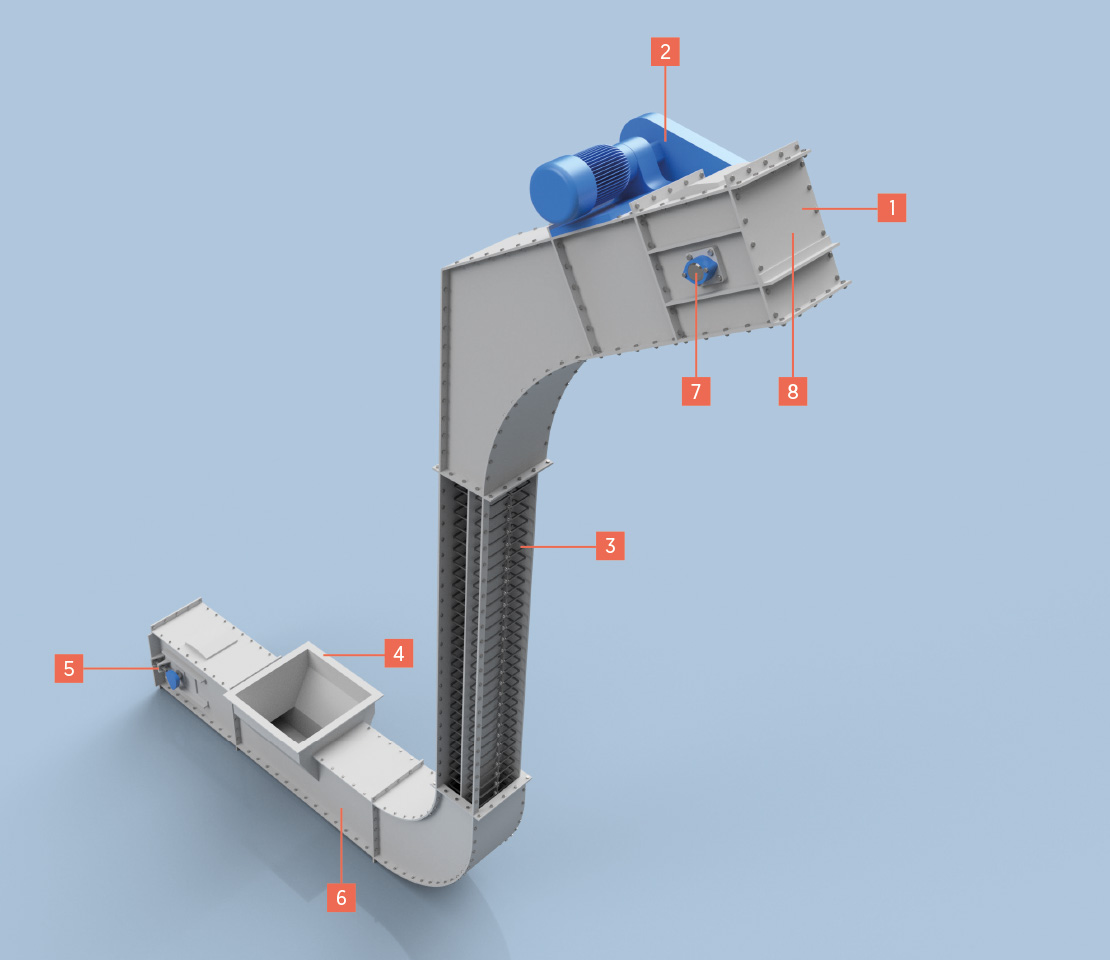

BulkMaster elevators employ the principal of en masse. The chain flight in its skeletal form is of a design that when immersed in the material will induce the whole mass of material to flow forward at the same speed in a solid, placid column within the casing of the conveyor. Elevator design allows the material to be moved in the horizontal then vertically or inclined plane or a combination of the two in a swan neck configuration.

King BulkMaster Elevators are manufactured in a standard range of sizes from 200 mm wide upwards enabling every customer requirement to be met.

- Totally enclosed casing.

- Integral or independently mounted drives.

- King high strength forged conveyor chain with robotically welded flights.

- Hopper inlets (optional metered delivery).

- Robust and effective chain tensioning.

- Heavy duty casing.

- Rotation sensor (optional).

- Blockage sensor (optional).

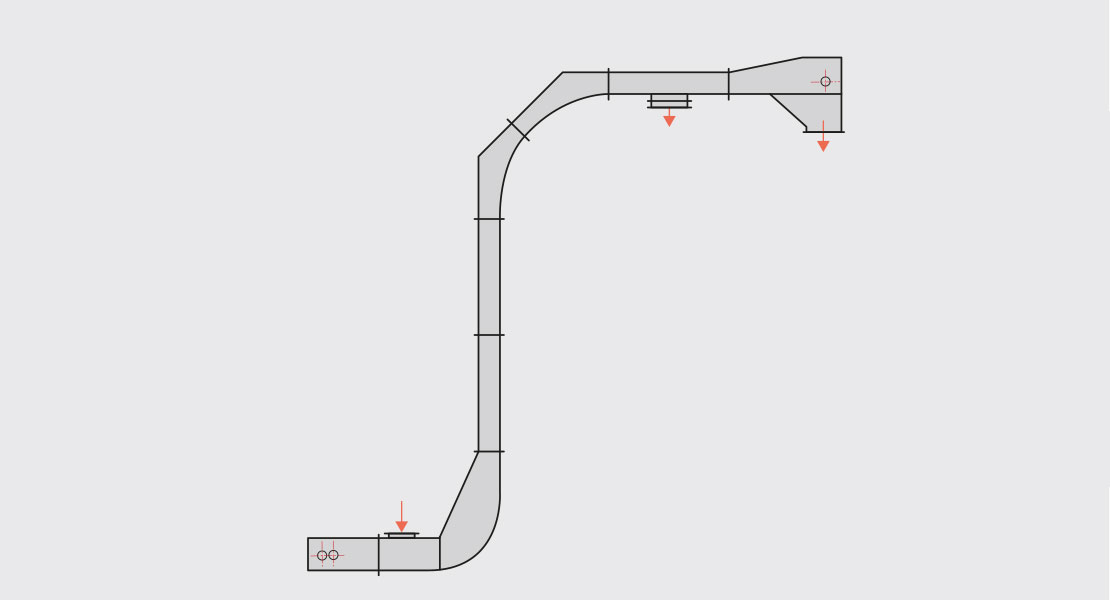

Popular BulkMaster Elevator arrangements

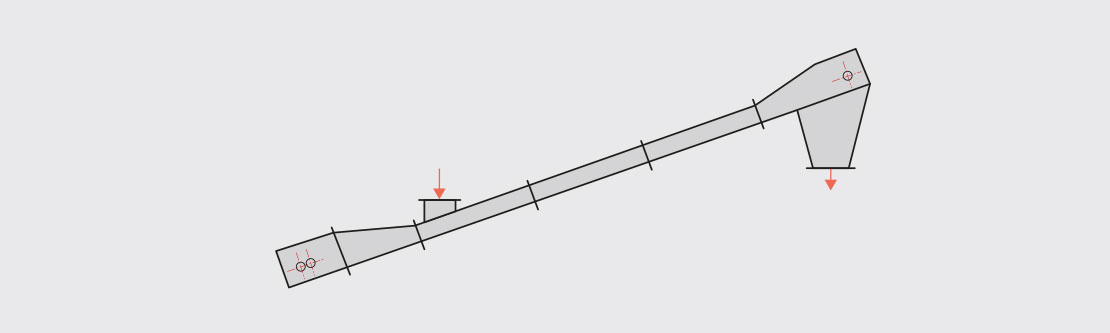

A. Standard straight running inclined elevator. Conventional tail shaft tensioning.

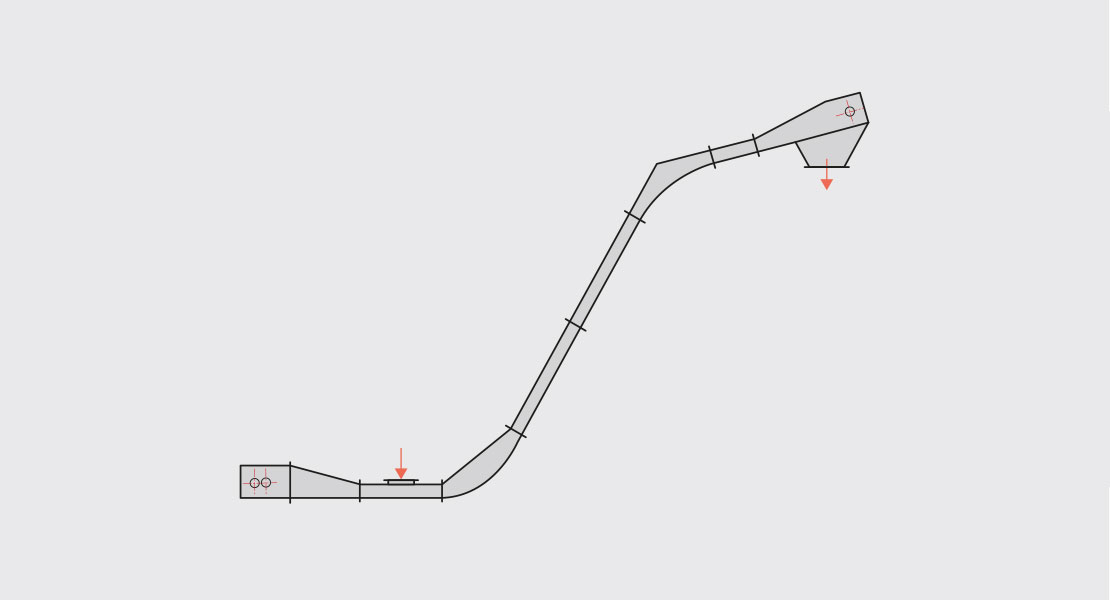

B. Swan neck elevator with loading on the horizontal section, a steep inlcline and final swan neck delivery section. Conventional tail shaft tensioning.

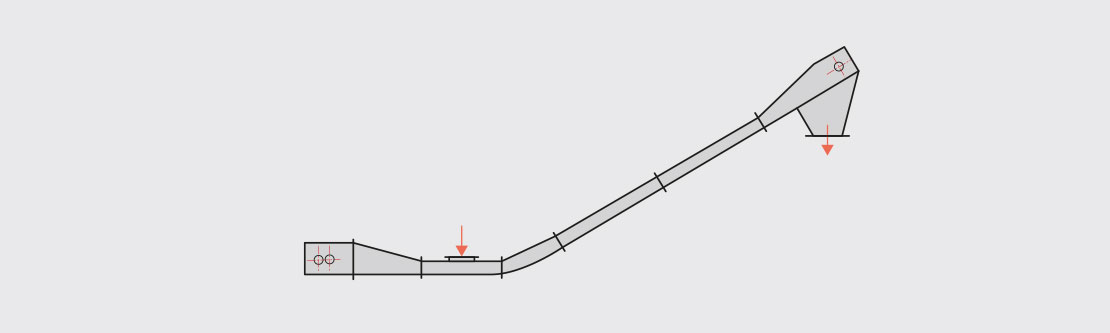

C. Elevator with single bend. Loading on the horizontal section with discharge hopper at the head of the inclined section. Conventional tail shaft tensioning.

D. Double bend conveyor. Loading on the horizonta section with 90 degree elevating section and final horizontal section with discharge at both intermediate and terminal positons. Conventinal tail shaft tensioning.