Forged conveyor chain

Have questions or need a quote?

Get in touch with the team today.

King manufacture an unrivalled range of high quality forged chains. The standard is for an alloy steel forging and pin case hardened for wear resistance. Specifications can be varied dependent on the operating environment.

|

Drop Forged Chain Links |

|||||||

|

Material reference |

JK Reference |

Material No |

Standard Hardening |

JK Heat Treatment Designation |

Standard hardening value |

Standard |

|

|

DIN |

AISI |

||||||

|

STANDARD QUALITIES |

|||||||

|

20CrMnTn |

TN |

1.8401 |

A29/A29M |

CASE HARDENING |

CH |

58-62 HRC |

0,8-1,0 mm |

|

42CrMo4 |

CD |

1.7225 |

4140 |

HARDENING AND TEMPERING |

TH |

1100-1300 N/mm² |

|

|

ALTERNATIVES ON REQUEST |

|||||||

|

18MnCrB5 |

BN |

1.7168 |

– |

CASE HARDENING |

CH |

58-62 HRC |

0,8-1,0 mm |

|

20MnCr5 |

MN |

1.7147 |

5120 |

CASE HARDENING |

CH |

58-62 HRC |

0,8-1,0 mm |

|

21NiCrMo4 |

CN |

1.6523 |

8620H |

CASE HARDENING |

CH |

58-62 HRC |

0,8-1,0 mm |

|

C45 |

C |

1.0503 |

1045 |

HARDENING AND TEMPERING |

TH |

800-900 N/mm² |

|

|

CORROSION AND ACID RESISTANT MATERIAL |

|||||||

|

X5CrNi 18-10 (V 2 A) |

SS304 |

1.4301 |

304 |

||||

|

X6CrNiMoTi 17-12 2 (V 4 A) |

SS316 |

1.4571 |

316 |

||||

|

X46Cr13 |

SS 420 |

1.4034 |

420 |

HARDENING AND TEMPERING |

TH |

50-52 HRC |

|

|

HEAT – RESISTANT MATERIAL |

|||||||

|

HEAT RESISTANCE IN AIR |

|||||||

|

X10CrAlSi7 |

JK HK |

1.4713 |

800° C MAX |

420-620 N/mm² |

|||

|

X15CrNiSi 20-12 |

JK HH |

1.4828 |

309 |

1000°C MAX |

500-750 N/mm² |

||

|

Chain Pins |

|||||||

|

Material reference |

JK Reference |

Material No |

Standard Hardening |

JK Heat Treatment Designation |

Standard hardening value |

Standard |

|

|

DIN |

AISI |

||||||

|

STANDARD QUALITIES |

BS970 1991 |

||||||

|

16MnCr5 |

590M17 |

1.7131 |

5115 |

CASE HARDENING |

CH |

58-62 HRC |

0,8-1,0 mm |

|

15NiCr13 |

633M13 |

1.5752 |

3310 |

CASE HARDENING |

CH |

58-62 HRC |

0,8-1,0 mm |

|

18CrNi8 |

1.592 |

CASE HARDENING |

CH |

58-62 HRC |

0,8-1,0 mm |

||

|

C45 |

080M46 |

1.0503 |

1045 |

INDUCTION HARDENING |

IH |

52-56 HRC |

1,5-2,0 mm |

|

HARDENING AND TEMPERING |

TH |

45-50 HRC |

|||||

|

42CrMo4 |

708M40 |

1.7225 |

4140 |

INDUCTION HARDENING |

IH |

56-60 HRC |

1,5-2,0 mm |

|

HARDENING AND TEMPERING |

TH |

56-60HRC |

|||||

|

CORROSION AND ACID RESISTANT MATERIAL |

|||||||

|

X46Cr13 |

420S29 |

1.4034 |

420 |

HARDENING AND TEMPERING |

TH |

50-52 HRC |

|

|

X105CrMo17 |

440S49 |

1.4125 |

440 |

HARDENING AND TEMPERING |

TH |

50-55 HRC |

|

|

Circlips |

|||||||

|

Material reference |

JK Reference |

Material No |

Standard Hardening |

JK Heat Treatment Designation |

Standard hardening value |

Standard |

|

|

DIN |

AISI |

||||||

|

STANDARD QUALITIES |

|||||||

|

DD12 |

P12 |

1.0398 |

621 |

||||

|

Ferritic – Cromweld 3Cr12 |

SS410 |

1.4003 |

410 |

||||

|

Austenitic |

SS304 |

1.4301 |

303 |

||||

|

Bushes |

||||||

|

Material reference |

JK Reference |

Material No |

Standard Hardening |

JK Heat Treatment Designation |

Standard hardening value |

|

|

DIN |

AISI |

|||||

|

STANDARD QUALITIES |

||||||

|

C 67 S |

070A72 |

1.1231 |

1070 |

HARDENING AND TEMPERING |

TH |

420-500 HV |

|

55 SI 7 |

1.5026 |

9255 |

HARDENING AND TEMPERING |

TH |

410-500 HV |

|

|

CORROSION AND ACID RESISTANT MATERIAL |

||||||

|

X 5 CR NI 18-10 (V 2 A) |

SS304 |

1.4301 |

304 |

|||

|

X 6 CR NI MO TI 17-12 2 (V 4 A) |

SS316 |

1.4571 |

316 |

|||

|

X 46 CR 13 |

SS420 |

1.4034 |

420 |

HARDENING AND TEMPERING |

TH |

42-49 HRC |

|

X 7 CR NI AL 17-7 |

SS630 |

1.4568 |

630 |

PRECIPITATION HARDENING |

PH |

400-480 HV |

|

Chain Flights |

||||||

|

Material reference |

JK Reference |

Material No |

Standard Hardening |

JK Heat Treatment Designation |

Standard hardening value |

|

|

DIN |

AISI |

|||||

|

STANDARD QUALITIES |

||||||

|

S 235 JR |

S235 |

1.0038 |

1018 |

|||

|

S 355 J2 |

S355 |

1.0577 |

1036 |

|||

|

C 45 |

080M46 |

1.0503 |

1045 |

|||

|

AR400 |

HP400 |

XAR400 |

HARDENING AND TEMPERING |

TH |

400 Bnh |

|

|

AR500 |

HP500 |

XAR500 |

HARDENING AND TEMPERING |

TH |

500 Bnh |

|

|

CORROSION AND ACID RESISTANT MATERIAL |

||||||

|

X 5 CR NI 18-10 (V 2 A) |

SS304 |

1.4301 |

304 |

|||

|

X 6 CR NI MO TI 17-12-2 (V 4 A) |

SS316 |

1.4571 |

316 |

|||

|

HEAT – RESISTANT MATERIAL |

||||||

|

HEAT RESISTANCE IN AIR |

||||||

|

X 10 CR AL SI 7 |

JKHK |

1.4713 |

MAX 800°C |

|||

|

X 15 CR NI SI 20-12 |

JKHH |

1.4828 |

310 |

MAX 1200²C |

||

|

Sprocket Segments |

||||||

|

Material reference |

JK Reference |

Material No |

Heat Treatment |

JK Heat Treatment Designation |

Maximum surface Hardness (hrc) |

|

|

DIN |

AISI |

|||||

|

C45 |

080M46 |

1.0503 |

1045 |

INDUCTION HARDENED |

IH |

60 (3+2mm) |

|

34 CR MO 4 |

708A37 |

1.7220 |

4135 |

INDUCTION HARDENED |

IH |

57 (3+2 mm) |

|

42 CR MO 4 |

708A42 |

1.7225 |

4142 |

INDUCTION HARDENED |

IH |

61 (3+2 mm) |

|

Idler Wheel |

||||||

|

Material reference |

JK Reference |

Material No |

Heat Treatment |

JK Heat Treatment Designation |

Maximum surface Hardness (hrc) |

|

|

DIN |

AISI |

|||||

|

C45 |

080M46 |

1.0503 |

1045 |

INDUCTION HARDENED |

IH |

60 (3+2 mm) |

Flights are robotically welded in one of three manufacturing facilities in the UK, Poland and the USA. The integrity of the welding is fundamental to best performance.

The configuration will vary dependent on the style of machine.

Flight attachment options

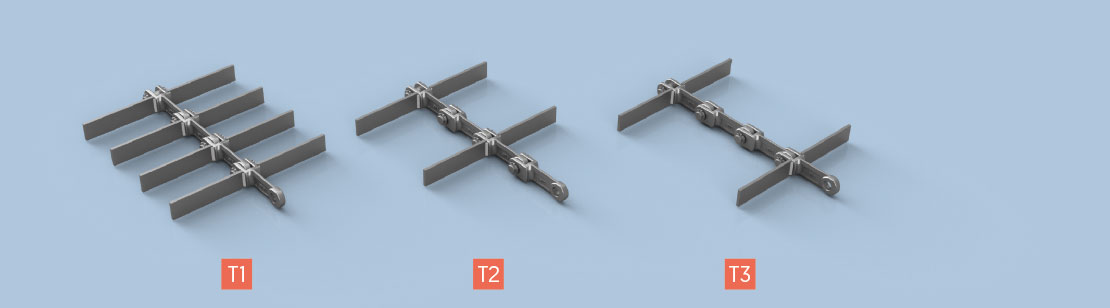

T Type Attachments for Horizontal and Slightly Inclined Conveying

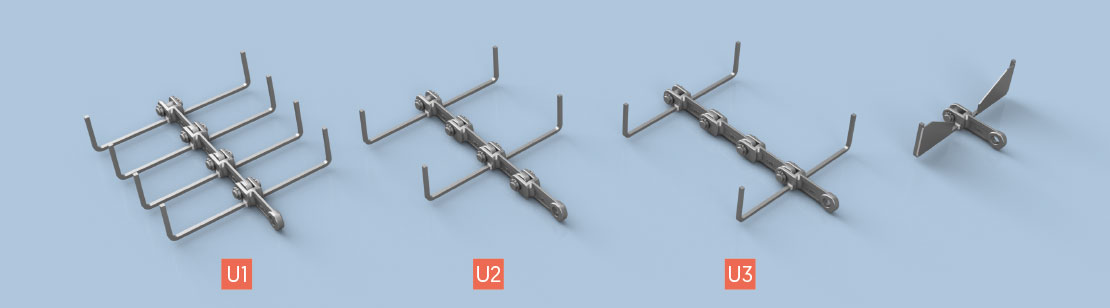

U Type Attachments for Horizontal and Inclined Conveying (with or without blanking plate)

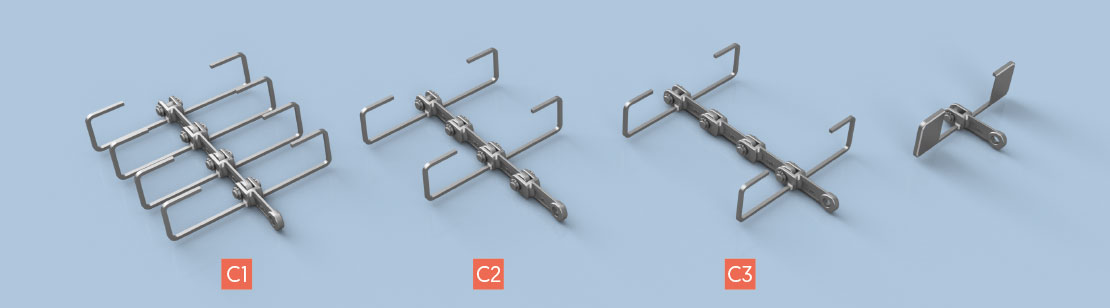

C Type Attachments for Horizontal, Inclined and Vertical Conveying (with or without blanking plate)

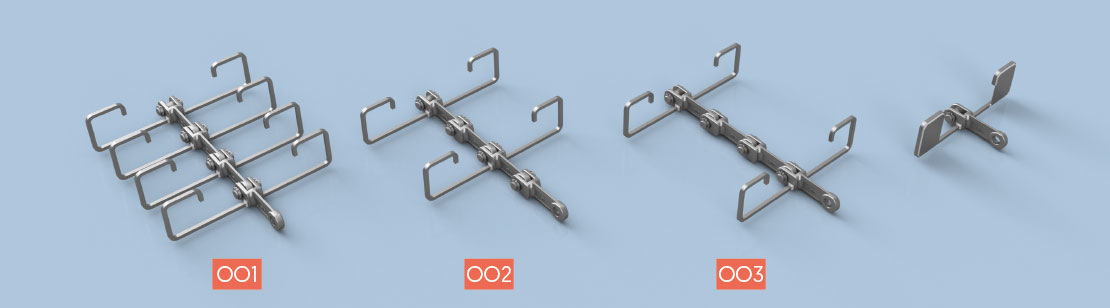

OO Type Attachments for Horizontal and Inclined Conveying (with or without blanking plate)

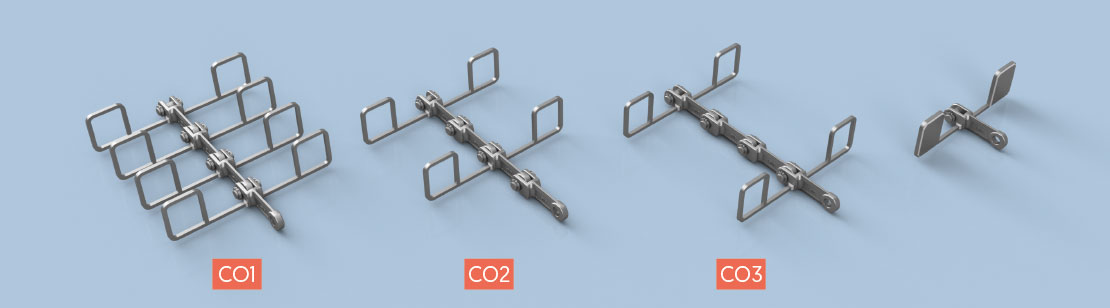

CO Type Attachments for Horizontal and Inclined Conveying (with or without blanking plate)

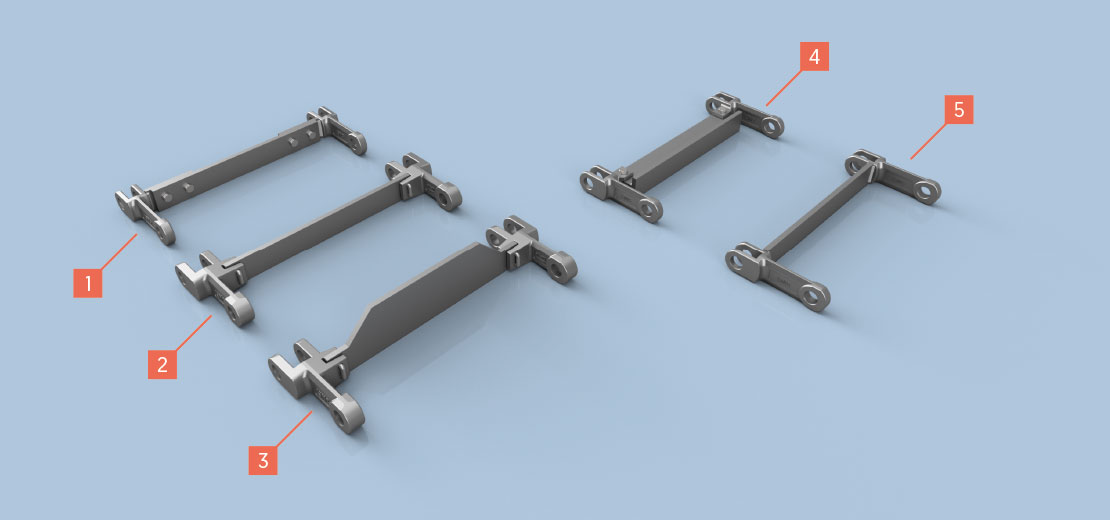

Double Series Flight Options I Format

- Standard Flight Bolted Construction

- Standard Flight U Clip Retention

- Deep Style U Clip Retention

- Reinforced flight with swivel arrangement

- Standard Flight Welded Construction