RHINO Cast Combination Chains for Log Infeed Conveyors

Have questions or need a quote?

Get in touch with the team today.

The Rhino series chain calls on John King’s long experience going back to the middle of the last century as Manufacturers of cast link chains. In the case of Rhino series both centre block and sidebars are produced from a high alloy direct hardening steel according to JK/ BT3. This is employed in the hardened and tempered condition at a level that maximises the mechanical properties in high duty applications where high impact and abrasion are commonplace. The chain has proven its value in the most demanding timber applications Worldwide.

|

RHINO Cast Combination Chains for Log Infeed Conveyors |

|||||||||||||||

|

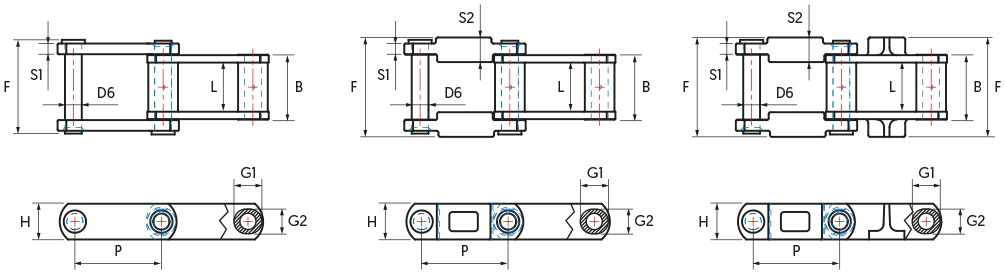

Chain |

Style |

Units |

Pitch |

Pins |

G1 |

G2 |

Over-All |

Between Sidebars |

Length of Bearing |

Sidebars |

Maximum Working Load |

Ultimate Strength |

Average Weight |

||

|

Diameter |

Thickness |

Height |

|||||||||||||

|

P |

D6 |

F |

L |

B |

S1 |

S2 |

H |

||||||||

|

JKC124/HD |

I |

in |

4.06 |

0.88 |

1.88 |

1.63 |

4.75 |

2.00 |

3.00 |

0.63 |

– |

2.00 |

22,800 lbs |

148,600 lbs |

14.9 lbs/ft |

|

mm |

103.12 |

22.35 |

47.75 |

41.40 |

120.65 |

50.80 |

76.20 |

16.00 |

– |

50.80 |

10,342 kg |

67,404 kg |

22.2 kg/m |

||

|

JKC132/HD |

II |

in |

6.05 |

1.09 |

2.00 |

1.75 |

6.81 |

3.31 |

4.31 |

0.75 |

– |

2.00 |

32,800 lbs |

214,000 lbs |

16.3 lbs/ft |

|

mm |

153.67 |

27.69 |

50.80 |

44.45 |

172.97 |

84.07 |

109.47 |

19.05 |

– |

50.80 |

14,878 kg |

97,069 kg |

24.3 kg/m |

||

|

JKC155/HD |

I |

in |

6.05 |

1.13 |

2.00 |

1.75 |

6.69 |

3.31 |

4.31 |

0.75 |

1.64 |

2.50 |

35,000 lbs |

230,000 lbs |

20.7 lbs/ft |

|

mm |

153.67 |

28.70 |

50.80 |

44.45 |

169.93 |

84.07 |

109.47 |

19.05 |

41.66 |

63.50 |

15,876 kg |

104,326 kg |

30.8 kg/m |

||

|

JKC155P/HD |

II |

in |

6.05 |

1.13 |

2.00 |

1.75 |

6.69 |

3.31 |

4.31 |

0.75 |

1.64 |

2.50 |

35,000 lbs |

230,000 lbs |

23.0 lbs/ft |

|

mm |

153.67 |

28.70 |

50.80 |

44.45 |

169.93 |

84.07 |

109.47 |

19.05 |

41.66 |

63.50 |

15,876 kg |

104,326 kg |

34.2 kg/m |

||

|

JKC157/HD |

I |

in |

6.08 |

1.22 |

2.13 |

1.84 |

6.95 |

3.38 |

4.63 |

0.84 |

1.73 |

2.50 |

41,800 lbs |

270,000 lbs |

23.6 lbs/ft |

|

mm |

154.43 |

30.99 |

54.10 |

46.74 |

176.53 |

85.85 |

117.60 |

21.34 |

43.94 |

63.50 |

18,960 kg |

122,470 kg |

35.1 kg/m |

||

|

JKC157P/HD |

II |

in |

6.08 |

1.22 |

2.13 |

1.84 |

6.95 |

3.38 |

4.63 |

0.84 |

1.73 |

2.50 |

41,800 lbs |

270,000 lbs |

24.8 lbs/ft |

|

mm |

154.43 |

30.99 |

54.10 |

46.74 |

176.53 |

85.85 |

117.60 |

21.34 |

43.94 |

63.50 |

18,960 kg |

122,470 kg |

36.9 kg/m |

||

|

JKC159P/HD |

II |

in |

6.13 |

1.28 |

2.25 |

2.00 |

6.95 |

3.37 |

4.62 |

0.84 |

1.73 |

3.00 |

50,000 lbs |

324,000 lbs |

28.8 lbs/ft |

|

mm |

155.70 |

32.51 |

57.15 |

50.80 |

176.53 |

85.60 |

117.35 |

21.34 |

43.94 |

76.20 |

22,680 kg |

146,964 kg |

42.9 kg/m |

||

John King RHINO range are the strongest, most wear resistant chain systems available designed to offer a simplified and robust constriction as compared to the original OEM selection.

They are produced from cast alloy steels that provide the optimum combination of impact, fatigue and wear performance. John Kings were the innovators in cast link combination chains. There is nothing new about the one piece casting technology. It is our focus on continuous improvement that has made this product the best option in the market place.

The versatility of cast link chains can be highlighted in the material options. For the Rhino range chains can be produced in a multiplicity of material grades commensurate with the environment and the duty. John King offer two standards for best and proven performance. Other cast materials are available on request.

|

Material table |

||||||||||||||||

|

John King |

British Standard Material Designation |

American Material Designation |

DIN |

CHEMICAL COMPOSITION |

Tensile Strength |

Proof Stress |

CHARPY (impact value at 20oC unless otherwise shown) |

Brinell Hardness |

Elongation |

|||||||

|

C |

Si |

Mn |

S |

P |

Cr |

Ni |

Mo |

|||||||||

|

% |

N/mm2 (T/in2) |

Joules |

HBW |

% |

||||||||||||

|

ALLOY STEELS |

||||||||||||||||

|

JK/BT3 |

BS10283 BT3 |

AISI 8630 |

1.6546 |

0.28-0.33 |

0.15-0.30 |

0.65-0.95 |

0,03 |

0,03 |

0.40-0.60 |

0.35-0.75 |

0.15-0.25 |

1000-1160 (65-75) |

695 (45) |

20 |

293-341 |

6 |

|

WEAR RESISTANT STEELS |

||||||||||||||||

|

JK/MN |

BS10283 BW10 |

AISI A128 Grade A |

1.3401 |

1.00-1.25 |

1,00 |

11.00 min |

0,06 |

0,07 |

2 |

– |

– |

– |

– |

– |

– |

– |

Note: Add suffix MN or BT3 to chain code to denote material grade employed.