Truck Dump Sprocket Conversion – Board Plant – North America

Have questions or need a quote?

Get in touch with the team today.

Truck Dump Sprocket Conversion – Board Plant – North America

The application is a truck dump drive sprocket, handling wood chip. Success of the product in Europe and US is attracting interest whereby the customer is looking for an improved design to reduce cost of ownership, downtime, maintenance and improved safety rating.

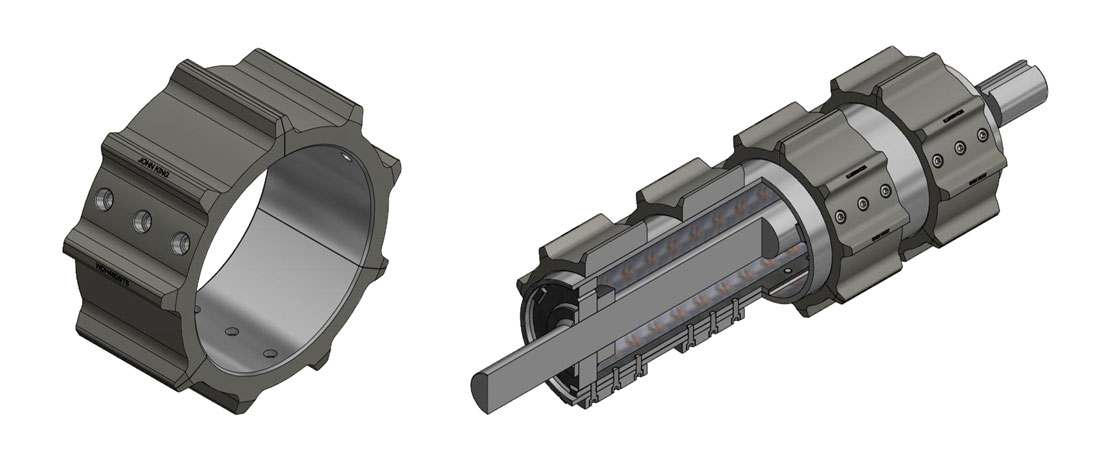

John Kings have designed and implemented a complete drop in drive unit, that when required, removable sprocket segmental teeth are the only sacrificial component that need replacing. Additionally, this results in spares that can be kept on site and tooth replacement can be carried out in hours v’s days.

The level of work and cost involved in removing an entire shaft and sprockets of a truck dump is without question a capital project. It requires a site service team and many manual labor hours to remove and replace.

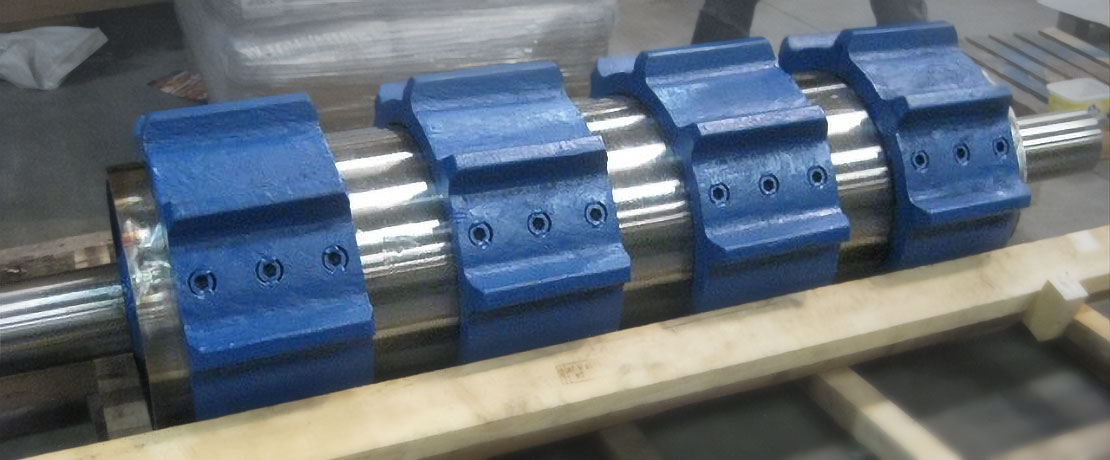

See photos and CAD 3D design of finished parts. This design can be adapted for all WDH chains from WDH110 to WDH680. We also have several similar designs for all welded steel chains from WH78 up to WH159.

Conclusion: This design may be more costly from the start, however in the long run there is huge reductions in TCO (total cost of ownership). Feedback so far is that capital project money can be spent elsewhere to improve the overall production of the facility.

We strive to continuously improve and innovate to provide our customer with the very best material handling solutions.