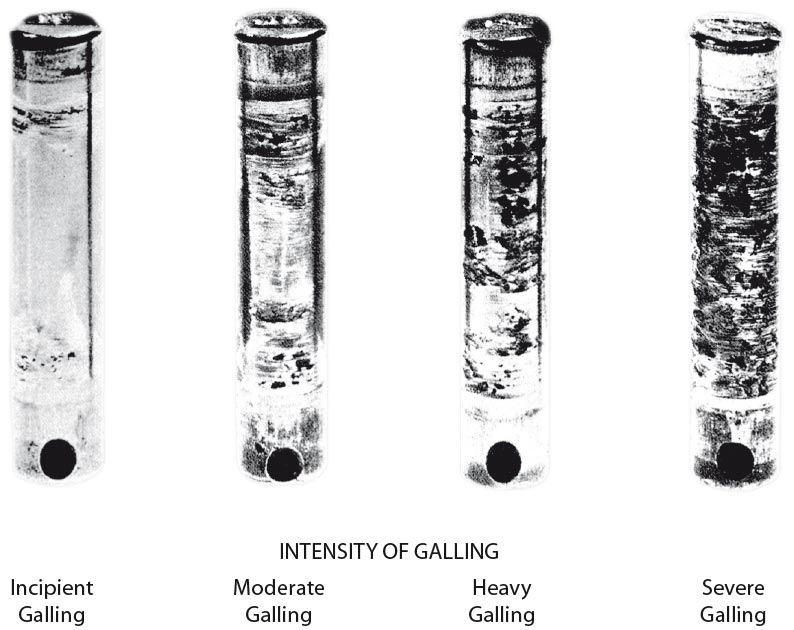

21.4 Pin wear from galling

Have questions or need a quote?

Get in touch with the team today.

Adhesive wear or galling occurs when minute points on the pin and bushing contact surfaces are microwelded together. As the surfaces interact during articulation over the sprockets the welded point is torn away as a particle of wear.

The primary purpose of lubrication is to create an effective film of oil between bearing surfaces to prevent direct metal to metal contact. Chain pins can become galled if the film is unavailable or ineffective. The scale of the galling depends on the degree and duration of the metal on metal contact.

Operation of chain for short periods under extreme load or excessive speed could cause incipient or moderate galling. This galling condition may not have a long terms impact on the chain as long as the condition is arrested. More intense forms of galling may be observed when heavily loaded chains operate at either very low or very high speeds.

Galling is more likely to occur early on in the operational life of a chain during a period when bearing surfaces are “bedding in”. Commissioning and maintenance procedures are therefore critical to ensure that the chain is not subject to adverse conditions during this critical period (See notes on commissioning in section 19).