21.2 Pin Wear from abrasion

Have questions or need a quote?

Get in touch with the team today.

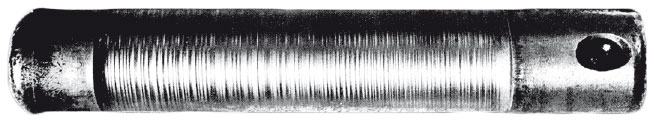

Wear will always take place where there is motion and contact between two surfaces such as is experienced in the articulation of a chain pin within the link barrel (or chain bush). The key is the rate of such wear and the presence of an abrasive material or inadequate lubrication between the contact surfaces will accelerate that wear. fig. 21.2.1 shows a chain pin operating in a dusty environment with high silica content. These abrasives penetrated the chain joints causing accelerated wear and a substantial reduction in the effective service life of the chain.

Cleaning and re-lubrication can help extend life of the chain. Where possible to use deflector plates directing material to the centre of a conveyor and limiting chain and material contact will also work to advantage. In some cases King have introduced grease lubrication through the bearing pin, a typical example is cement clinker pan conveyors. Lubrication is introduced into the joints of the chain through a grease way. This has the benefit of purging contaminated grease and replacing it with new. It is essential that this routine is maintained since contaminated grease can act as an abrasive paste and create a reverse effect to that anticipated.

Where lubrication is difficult or impossible it is necessary to rely on an optimum material and heat treatment selection. The harder the bearing surface and the longer it remains intact the more extended the chain life. John King technicians are available to assist in component selection.