21.14 Abnormal wear as a result of misalignment

Have questions or need a quote?

Get in touch with the team today.

Unusual wear patterns on chains can indicate a condition of misalignment which can cause severe damage to chain. The most common types of misalignment are:

- Shafts not parallel Misalignment between head and tail sprockets

- Misalignment on conveyor tracks

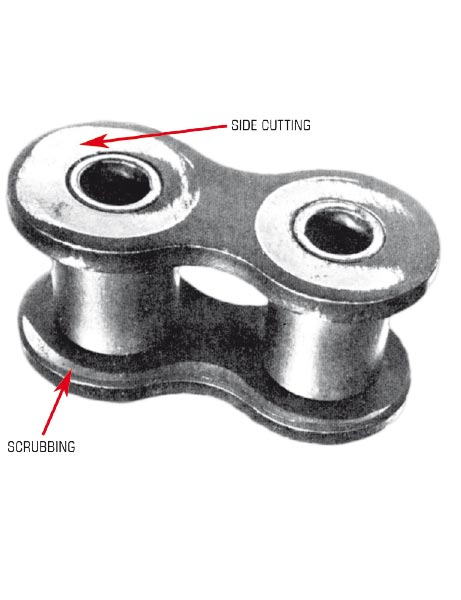

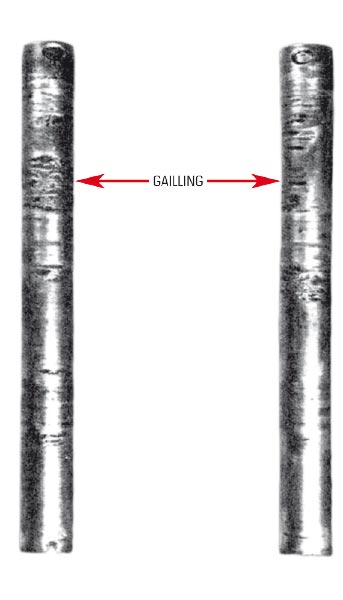

Possible consequences are overload to one side of the chain or chain twisting as the chain moves from one sprocket to another. Symptoms include pin galling, sidebar failure or rapid wear. On examination pin galling will be most accentuated at the end where overload is greatest. The condition will also cause scubbing between sidebars and sprocket teeth and side cutting increasing friction and in some cases loss of fit between components.

Misaligned conveyor track can create unequal wear. The curvature or camber that results induces a tendency for the chain to run to one side of the track or trough.

The best precaution is frequent inspection so if misalignment has developed it can be identified and addressed.