21.12.2 Roller/Bush crushing from high load concentration

Have questions or need a quote?

Get in touch with the team today.

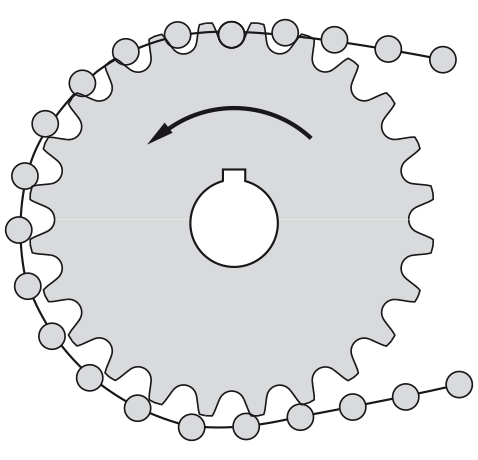

A similar condition to 21.12.1 can be seen when pitch extension causes malgearing on the sprockets As illustrated in fig. 21.12.2.1 some of the rollers or bushings may in “running out” contact the tips of the teeth. This can cause loads sufficiently high to cause crushing of the component. This condition is a clear indication of a need to change the chain. This is particularly common place on large diameter sprockets such as drum drive rings.

Conversely a similar condition can occur when a chain is operated on worn sprockets. For this very good reason KING always recommend replacement of chain and sprockets together. This will allow the running gear the best chance of achieving maximum service life.

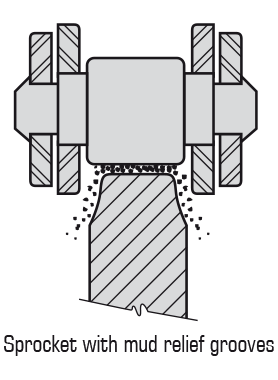

Rollers can also be damaged if rocks or other hard debris builds up in the tooth root. KING sprocket design allows a tooth form with increased bottom line clearance (see sprocket section for more information) or alternatively “mud relief” which is a scallop introduced to the root to allow material to fall away as detailed in fig. 21.12.2.2.