M Series Chains with Hollow Pin

Have questions or need a quote?

Get in touch with the team today.

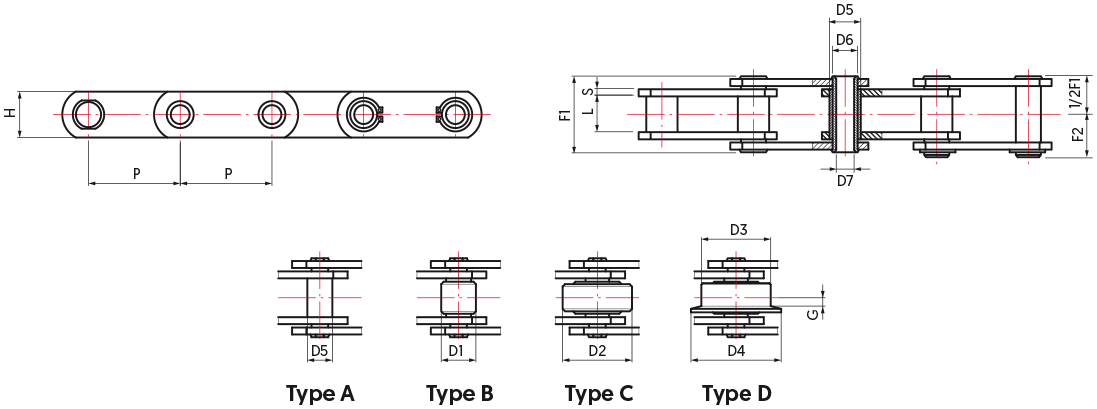

JOHN KING M series hollow pin chains are prefixed MC. Chain of this construction affords a ready facility for fixing attachments to the outer plates through the hollow pin. A typical application and often produced by JOHN KING is in pan conveyor systems notably for cement clinker transport where a carrying pan and cross bar are mounted between the two strands of chain.

|

Metric Conveyor Hollow Pin Chains ISO 1977 DIN 8167 |

||||||||||||||||

|

Chain |

Pitch |

Rollers |

Bushings |

Pins |

Over All Pin |

Between |

Sidebars |

Working |

Average |

|||||||

|

Style |

Flange |

Outer Diameter |

Inner |

Thickness |

Height |

|||||||||||

|

P |

D1 |

D2 |

D4 |

G |

D5 |

D6 |

D7 |

F1 |

F2 |

L |

S |

H |

Bush |

|||

|

mm |

kN |

kN* |

kg/m |

|||||||||||||

|

MC28 |

50 |

25 |

36 |

45 |

4.5 |

17 |

13 |

8.2 |

36 |

20 |

20 |

3 |

25 |

28 |

40 |

2.80 |

|

MC28 |

63 |

25 |

36 |

45 |

4.5 |

17 |

13 |

8.2 |

36 |

20 |

20 |

3 |

25 |

28 |

40 |

2.45 |

|

MC28 |

80 |

25 |

36 |

45 |

4.5 |

17 |

13 |

8.2 |

36 |

20 |

20 |

3 |

25 |

28 |

40 |

2.23 |

|

MC28 |

100 |

25 |

36 |

45 |

4.5 |

17 |

13 |

8.2 |

36 |

20 |

20 |

3 |

25 |

28 |

40 |

2.07 |

|

MC28 |

125 |

25 |

36 |

45 |

4.5 |

17 |

13 |

8.2 |

36 |

20 |

20 |

3 |

25 |

28 |

40 |

1.94 |

|

MC56 |

63 |

30 |

50 |

60 |

7 |

21 |

15.5 |

10.2 |

45 |

26 |

24 |

4 |

35 |

56 |

90 |

3.50 |

|

MC56 |

80 |

30 |

50 |

60 |

7 |

21 |

15.5 |

10.2 |

45 |

26 |

24 |

4 |

35 |

56 |

90 |

3.20 |

|

MC56 |

100 |

30 |

50 |

60 |

7 |

21 |

15.5 |

10.2 |

45 |

26 |

24 |

4 |

35 |

56 |

90 |

2.90 |

|

MC56 |

125 |

30 |

50 |

60 |

7 |

21 |

15.5 |

10.2 |

45 |

26 |

24 |

4 |

35 |

56 |

90 |

2.70 |

|

MC56 |

160 |

30 |

50 |

60 |

7 |

21 |

15.5 |

10.2 |

45 |

26 |

24 |

4 |

35 |

56 |

90 |

2.50 |

|

MC112 |

80 |

42 |

70 |

85 |

8.5 |

29 |

22 |

14.3 |

63 |

36 |

32 |

6 |

50 |

112 |

180 |

8.20 |

|

MC112 |

100 |

42 |

70 |

85 |

8.5 |

29 |

22 |

14.3 |

63 |

36 |

32 |

6 |

50 |

112 |

180 |

7.60 |

|

MC112 |

125 |

42 |

70 |

85 |

8.5 |

29 |

22 |

14.3 |

63 |

36 |

32 |

6 |

50 |

112 |

180 |

6.96 |

|

MC112 |

160 |

42 |

70 |

85 |

8.5 |

29 |

22 |

14.3 |

63 |

36 |

32 |

6 |

50 |

112 |

180 |

6.40 |

|

MC112 |

200 |

42 |

70 |

85 |

8.5 |

29 |

22 |

14.3 |

63 |

36 |

32 |

6 |

50 |

112 |

180 |

6.00 |

|

MC112 |

250 |

42 |

70 |

85 |

8.5 |

29 |

22 |

14.3 |

63 |

36 |

32 |

6 |

50 |

112 |

180 |

5.68 |

|

MC224 |

125 |

60 |

100 |

120 |

10.5 |

42 |

30 |

20.5 |

84 |

47 |

43 |

8 |

70 |

224 |

350 |

12.30 |

|

MC224 |

160 |

60 |

100 |

120 |

10.5 |

42 |

30 |

20.5 |

84 |

47 |

43 |

8 |

70 |

224 |

350 |

11.10 |

|

MC224 |

200 |

60 |

100 |

120 |

10.5 |

42 |

30 |

20.5 |

84 |

47 |

43 |

8 |

70 |

224 |

350 |

10.20 |

|

MC224 |

250 |

60 |

100 |

120 |

10.5 |

42 |

30 |

20.5 |

84 |

47 |

43 |

8 |

70 |

224 |

350 |

9.60 |

|

MC224 |

315 |

60 |

100 |

120 |

10.5 |

42 |

30 |

20.5 |

84 |

47 |

43 |

8 |

70 |

224 |

350 |

8.98 |

* Breaking Load With heat treated Plates