John King, creating a ‘chain’ reaction of improvements

Have questions or need a quote?

Get in touch with the team today.

John King, creating a ‘chain’ reaction of improvements

ORGANISATION

Hawaiian-Philippines Company (HPCo) Sugar

LOCATION

Silay City, Philippines

DATE

2018

Client Issue

On the main cane carrier chain at HPCo, the client was unable to get through a milling season with their previous competitors chain. This was due to excessive component wear, caused by cyclical overloading and therefore making the system extremely inefficient.

John King Exploration

Site Visit

John King Sugar Technical Manager, Chris Sweeney visited HPCo in the Philippines to provide a hands on investigation to get an overall assessment of the carrier and understand the reasons as to why the excessive and premature wear was taking place.

Calculated Chain Pull

In order to verify current loading on the chains a basic chain pull calculation was undertaken based on the factors provided:

Throughput: 350 TCH

Linear Speed: 36 ft/min

Slat weight: 28 kg

Conveyor width: 83”

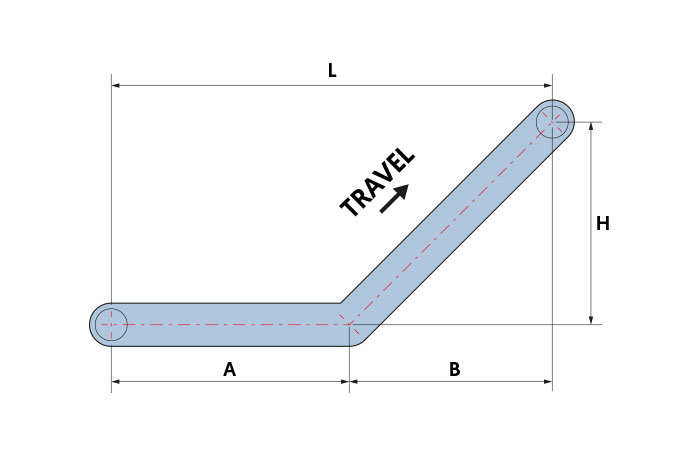

Conveyor dimensions: L: 149 ft, A: 61 ft, B: 88 ft, H: 20 ft

Results

Notwithstanding any other factors or the prevalent conditions within the application, the chain pull calculations show that the 09065 chain currently in use is vastly overloaded.

Not allowing for any service factors, the chain was calculated to be loaded to 127% of its allowable working load. Considering a conservative service factor of 1.4 this figure increases to 178%. Whilst the 09065 may have been sufficient for this specific application under previous / initial conditions, the current loading exceeds the working parameters for this chain, hence the excessive and premature wear exhibited.

The calculations show that the addition of a 4th strand of 09065 would not be sufficient to address the issue. Whilst reducing the pull per strand considerably the chain would still be loaded 141% of its allowable working load.

|

Chain |

No. of Strands |

Catalogued Working Load (Lbs) |

Total Chain Pull (Lbs) |

Pull Per Strand (Lbs) |

Total Chain Pull Service Factor 1.4 (Lbs) |

Pull Per Strand Service Factor 1.4 (Lbs) |

% of Working Load |

|

|

Current Set-up |

09065 K2 |

3 |

9,250.00 |

35,336 |

11,779 |

49,470 |

16,490 |

178.27 |

|

09065 K2 |

4 |

9,250.00 |

37,445 |

9,361 |

52,423 |

13,106 |

141.68 |

|

|

JKR2804 K2 |

3 |

24,300.00 |

39,856.00 |

13,285 |

55,798 |

18,599 |

76.54 |

John King Conclusion

The 09065 chain currently installed is not sufficient for the current loading of the main cane carrier at HPCO. Under the current circumstances it is highly unlikely that any 09065 chain could serve for much more than a single crushing season.

To address the issue with minimal modification to the conveyor a larger roller type chain with an increased working load was recommended to replace the existing 09065.

For the purposes of calculations, we used 3 strands of 8” pitch chain JKR2804, having a working load of 24,300Lbs. Under current conditions this chain would be loaded to within 68%. This would bring in comfortably within its working loaded limit, along with the benefit of scope for possible future increase in throughput. The disadvantage to this is that resources would have to be spent on modification work, with new slats and sprockets required to accommodate the 8” pitch chain.

Three other suggestions were made:

- Change to an outboard roller chain.

- Split of this one long conveyor into two separate conveyors.

- If HPCo were to persevere with chain 09065 then we would supply our HD heavy duty bush, giving greater bearing area which would improve the service life.

It should be noted that in the case of this specific conveyor, the service factor of 1.4 may not be sufficient. It was noted that the feed drum at the head of the conveyor was compressing the cane to such an extent where it adds considerable loading to the chains.

In fact, we have additional specific experience at Nakambala Factory in Zambia. Nakambala has a very similar arrangement utilizing 09065, with the same issues occurring. In the short term, we could assist with support structures at the most heavily loaded areas, but ultimately a different chain solution is required.

HPCo Action Taken

More confidence with new JK JKR09065 with HD ‘heavy duty’ bush

Although HPCo did not want to invest in the conveyor modifications that were needed for a larger chain that was suitable for the application they have purchased and introduced the John King JKR09065 with HD ‘heavy duty’ bush, which has given them confidence of a full crop.

Success

The John King JKR09065 chain supplied, comfortably lasted the first year and was refurbished with new components for a second crop.

Continual Support

Our local agent attends installation and regularly visits the plant to monitor the chain conditions and maintenance.