Sprockets with split construction are preferred for ease of replacement (Type TS). The tooth form incorporates John Kings unique profile allowing for increased gap angle and bottom line clearance to prevent material packing and reduced wear rate during operation.

FV Series Chains

Have questions or need a quote?

Get in touch with the team today.

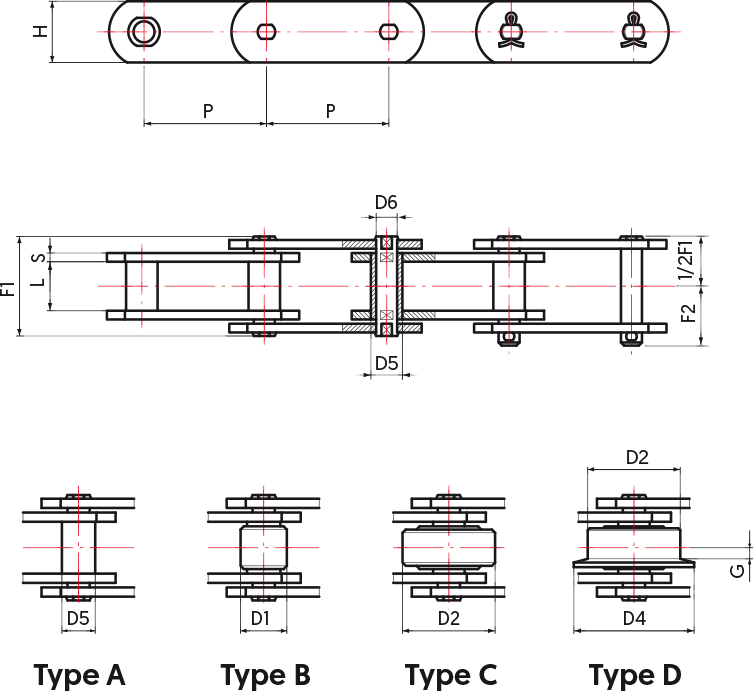

The second series of metric conveyor chains is the FV standard comparable to M but varying in dimensions and breaking strengths. Construction of the chains is equivalent to M as are the higher specification materials and heat treatments employed by John King.

|

FV Series Metric Conveyor Chains DIN 8165 |

|||||||||||||||

|

Chain |

Pitch |

Rollers |

Bushings |

Pins |

Over-All Pin & Cotter |

Between |

Sidebars |

Breaking |

|||||||

|

Style |

Flange |

Diameter |

Thickness |

Height |

|||||||||||

|

P |

D1 |

D2 |

D3 |

D4 |

G |

D5 |

D6 |

F1 |

F2 |

L |

S |

H |

DIN standard |

John King* |

|

|

mm |

kN |

||||||||||||||

|

FV63 |

63 |

26 |

40 |

50 |

63 |

5 |

18 |

12 |

45 |

26 |

22 |

4 |

30 |

64 |

75 |

|

FV63 |

80 |

26 |

40 |

50 |

63 |

5 |

18 |

12 |

45 |

26 |

22 |

4 |

30 |

64 |

75 |

|

FV63 |

100 |

26 |

40 |

50 |

63 |

5 |

18 |

12 |

45 |

26 |

22 |

4 |

30 |

64 |

75 |

|

FV63 |

125 |

26 |

40 |

50 |

63 |

5 |

18 |

12 |

45 |

26 |

22 |

4 |

30 |

64 |

75 |

|

FV63 |

160 |

26 |

40 |

50 |

63 |

5 |

18 |

12 |

45 |

26 |

22 |

4 |

30 |

64 |

75 |

|

FV90 |

63 |

30 |

48 |

63 |

78 |

6.5 |

20 |

14 |

53 |

30 |

25 |

5 |

35 |

100 |

115 |

|

FV90 |

80 |

30 |

48 |

63 |

78 |

6.5 |

20 |

14 |

53 |

30 |

25 |

5 |

35 |

100 |

115 |

|

FV90 |

100 |

30 |

48 |

63 |

78 |

6.5 |

20 |

14 |

53 |

30 |

25 |

5 |

35 |

100 |

115 |

|

FV90 |

125 |

30 |

48 |

63 |

78 |

6.5 |

20 |

14 |

53 |

30 |

25 |

5 |

35 |

100 |

115 |

|

FV90 |

160 |

30 |

48 |

63 |

78 |

6.5 |

20 |

14 |

53 |

30 |

25 |

5 |

35 |

100 |

115 |

|

FV90 |

200 |

30 |

48 |

63 |

78 |

6.5 |

20 |

14 |

53 |

30 |

25 |

5 |

35 |

100 |

115 |

|

FV90 |

250 |

30 |

48 |

63 |

78 |

6.5 |

20 |

14 |

53 |

30 |

25 |

5 |

35 |

100 |

115 |

|

FV112 |

100 |

32 |

55 |

72 |

90 |

7.5 |

22 |

16 |

62 |

35 |

30 |

6 |

40 |

120 |

170 |

|

FV112 |

125 |

32 |

55 |

72 |

90 |

7.5 |

22 |

16 |

62 |

35 |

30 |

6 |

40 |

120 |

170 |

|

FV112 |

160 |

32 |

55 |

72 |

90 |

7.5 |

22 |

16 |

62 |

35 |

30 |

6 |

40 |

120 |

170 |

|

FV112 |

200 |

32 |

55 |

72 |

90 |

7.5 |

22 |

16 |

62 |

35 |

30 |

6 |

40 |

120 |

170 |

|

FV112 |

250 |

32 |

55 |

72 |

90 |

7.5 |

22 |

16 |

62 |

35 |

30 |

6 |

40 |

120 |

170 |

|

FV140 |

100 |

36 |

60 |

80 |

100 |

9 |

26 |

18 |

67 |

41 |

35 |

6 |

45 |

145 |

180 |

|

FV140 |

125 |

36 |

60 |

80 |

100 |

9 |

26 |

18 |

67 |

41 |

35 |

6 |

45 |

145 |

180 |

|

FV140 |

160 |

36 |

60 |

80 |

100 |

9 |

26 |

18 |

67 |

41 |

35 |

6 |

45 |

145 |

180 |

|

FV140 |

200 |

36 |

60 |

80 |

100 |

9 |

26 |

18 |

67 |

41 |

35 |

6 |

45 |

145 |

180 |

|

FV140 |

250 |

36 |

60 |

80 |

100 |

9 |

26 |

18 |

67 |

41 |

35 |

6 |

45 |

145 |

180 |

|

FV180 |

125 |

42 |

70 |

100 |

125 |

13 |

30 |

20 |

86 |

51 |

45 |

8 |

50 |

190 |

250 |

|

FV180 |

160 |

42 |

70 |

100 |

125 |

13 |

30 |

20 |

86 |

51 |

45 |

8 |

50 |

190 |

250 |

|

FV180 |

200 |

42 |

70 |

100 |

125 |

13 |

30 |

20 |

86 |

51 |

45 |

8 |

50 |

190 |

250 |

|

FV180 |

250 |

42 |

70 |

100 |

125 |

13 |

30 |

20 |

86 |

51 |

45 |

8 |

50 |

190 |

250 |

|

FV180 |

315 |

42 |

70 |

100 |

125 |

13 |

30 |

20 |

86 |

51 |

45 |

8 |

50 |

190 |

250 |

|

FV250 |

160 |

50 |

80 |

125 |

150 |

15 |

36 |

26 |

97 |

56 |

55 |

8 |

60 |

275 |

300 |

|

FV250 |

200 |

50 |

80 |

125 |

150 |

15 |

36 |

26 |

97 |

56 |

55 |

8 |

60 |

275 |

300 |

|

FV250 |

250 |

50 |

80 |

125 |

150 |

15 |

36 |

26 |

97 |

56 |

55 |

8 |

60 |

275 |

300 |

|

FV250 |

315 |

50 |

80 |

125 |

150 |

15 |

36 |

26 |

97 |

56 |

55 |

8 |

60 |

275 |

300 |

|

FV315 |

160 |

60 |

90 |

140 |

175 |

18 |

42 |

30 |

116 |

66 |

65 |

10 |

70 |

370 |

480 |

|

FV315 |

200 |

60 |

90 |

140 |

175 |

18 |

42 |

30 |

116 |

66 |

65 |

10 |

70 |

370 |

480 |

|

FV315 |

250 |

60 |

90 |

140 |

175 |

18 |

42 |

30 |

116 |

66 |

65 |

10 |

70 |

370 |

480 |

|

FV315 |

315 |

60 |

90 |

140 |

175 |

18 |

42 |

30 |

116 |

66 |

65 |

10 |

70 |

370 |

480 |

|

FV315 |

400 |

60 |

90 |

140 |

175 |

18 |

42 |

30 |

116 |

66 |

65 |

10 |

70 |

370 |

480 |

|

FV400 |

160 |

60 |

100 |

150 |

185 |

20 |

44 |

32 |

132 |

76 |

70 |

12 |

70 |

400 |

640 |

|

FV400 |

200 |

60 |

100 |

150 |

185 |

20 |

44 |

32 |

132 |

76 |

70 |

12 |

70 |

400 |

640 |

|

FV400 |

250 |

60 |

100 |

150 |

185 |

20 |

44 |

32 |

132 |

76 |

70 |

12 |

70 |

400 |

640 |

|

FV400 |

315 |

60 |

100 |

150 |

185 |

20 |

44 |

32 |

132 |

76 |

70 |

12 |

70 |

400 |

640 |

|

FV400 |

400 |

60 |

100 |

150 |

185 |

20 |

44 |

32 |

132 |

76 |

70 |

12 |

70 |

400 |

640 |

|

FV500 |

160 |

70 |

110 |

160 |

195 |

21 |

50 |

36 |

142 |

81 |

80 |

12 |

80 |

500 |

750 |

|

FV500 |

200 |

70 |

110 |

160 |

195 |

21 |

50 |

36 |

142 |

81 |

80 |

12 |

80 |

500 |

750 |

|

FV500 |

250 |

70 |

110 |

160 |

195 |

21 |

50 |

36 |

142 |

81 |

80 |

12 |

80 |

500 |

750 |

|

FV500 |

315 |

70 |

110 |

160 |

195 |

21 |

50 |

36 |

142 |

81 |

80 |

12 |

80 |

500 |

750 |

|

FV500 |

400 |

70 |

110 |

160 |

195 |

21 |

50 |

36 |

142 |

81 |

80 |

12 |

80 |

500 |

750 |

|

FV500 |

500 |

70 |

110 |

160 |

195 |

21 |

50 |

36 |

142 |

81 |

80 |

12 |

80 |

500 |

750 |

* Breaking Load with heat treated Plates

|

Weight Table |

|||||

|

Chain |

Pitch |

Average Weight |

|||

|

P |

Type A |

Type B |

Type C |

Type D |

|

|

mm |

kg/m |

||||

|

FV90 |

63 |

4.84 |

5.98 |

9.17 |

– |

|

FV90 |

80 |

4,40 |

5.52 |

8.12 |

– |

|

FV90 |

100 |

4.07 |

4.78 |

6.79 |

9.59 |

|

FV90 |

125 |

3.80 |

4.38 |

5.98 |

8.22 |

|

FV90 |

160 |

3.57 |

4.02 |

5.28 |

7.02 |

|

FV90 |

200 |

3.41 |

3.76 |

4.77 |

6.17 |

|

FV90 |

250 |

3.28 |

3.56 |

4.37 |

5.48 |

|

FV112 |

100 |

5.84 |

6.78 |

10.27 |

14.95 |

|

FV112 |

125 |

5.43 |

6.18 |

8.97 |

12.71 |

|

FV112 |

160 |

5.06 |

5.65 |

7.83 |

10.76 |

|

FV112 |

200 |

4.80 |

5.27 |

7.02 |

9.36 |

|

FV112 |

250 |

4.60 |

4.97 |

6.37 |

8.24 |

|

FV140 |

100 |

7.09 |

8.34 |

12.98 |

19.63 |

|

FV140 |

125 |

6.52 |

7.52 |

11.23 |

16.55 |

|

FV140 |

160 |

6.02 |

6.81 |

9.70 |

13.86 |

|

FV140 |

200 |

5.66 |

6.29 |

8.61 |

11.94 |

|

FV140 |

250 |

5.38 |

5.88 |

7.74 |

10.10 |

|

FV180 |

125 |

10.04 |

11.87 |

18.44 |

30.70 |

|

FV180 |

160 |

9.22 |

10.85 |

15.78 |

25.36 |

|

FV180 |

200 |

8.63 |

9.77 |

13.88 |

21.54 |

|

FV180 |

250 |

8.16 |

9.07 |

12.36 |

18.49 |

|

FV180 |

315 |

7.77 |

8.50 |

11.11 |

15.97 |

|

FV250 |

160 |

12.11 |

14.56 |

22.25 |

42.01 |

|

FV250 |

200 |

11.19 |

13.16 |

19.30 |

35.11 |

|

FV250 |

250 |

10.46 |

12.03 |

16.95 |

29.60 |

|

FV250 |

315 |

9.86 |

11.10 |

15.01 |

25.05 |

|

FV315 |

160 |

18.76 |

23.22 |

33.83 |

– |

|

FV315 |

200 |

17.21 |

20.78 |

29.26 |

53.72 |

|

FV315 |

250 |

15.96 |

18.82 |

25.60 |

45.18 |

|

FV315 |

315 |

14.94 |

17.20 |

22.59 |

38.12 |

|

FV315 |

400 |

14.10 |

15.88 |

20.12 |

32.36 |

|

FV400 |

160 |

22.06 |

26.41 |

39,80 |

– |

|

FV400 |

200 |

20.29 |

23.77 |

36.45 |

66.19 |

|

FV400 |

250 |

18.87 |

21.65 |

31.79 |

55.59 |

|

FV400 |

315 |

17.70 |

19.91 |

27.95 |

46.84 |

|

FV400 |

400 |

16.74 |

18.48 |

24.82 |

39.69 |

|

FV500 |

160 |

27.07 |

34.28 |

54.41 |

– |

|

FV500 |

200 |

24.67 |

30.44 |

46.55 |

83.05 |

|

FV500 |

250 |

22.75 |

27.36 |

40.25 |

69.05 |

|

FV500 |

315 |

21.17 |

24.83 |

35.06 |

58.23 |

|

FV500 |

400 |

19.87 |

22.76 |

30.81 |

49.06 |

|

FV500 |

500 |

18.91 |

21.22 |

27.66 |

42.26 |

FV63 – FV180 chains: Pressed bush with welded or riveted pin

FV250 – FV500 chains: Welded or pressed bush with welded or riveted pin

Special attention should be applied to options in construction.

John King EXCEL standard SFS2380

For M series (DIN 8167) and FV series (DIN 8165) John King offer an uprated version to improve performance within more demanding applications. This comes under the Scandinavian standard SFS2380. Dimensionally as M and FV series, but with pin and bush welded to the side plates. This has the immediate and positive effect of increasing breaking strength by up to 50% as well as improving impact resistance, shock loading and general service performance.

Sprockets for Metric Chains

Sprockets of segmental construction include bolt on tooth rings for obvious benefit in replacement (Type CS). The tooth form incorporates John Kings unique profile allowing for increased gap angle and bottom line clearance to prevent material packing and reduced wear rate during operation.

Material options:

- BS970 080M40 carbon steel suitable for surface hardening to 550Bnh at a minimum effective depth of 2.5 mm

- BS EN 10025 S355J2 high strength steel

- Other options available on request.