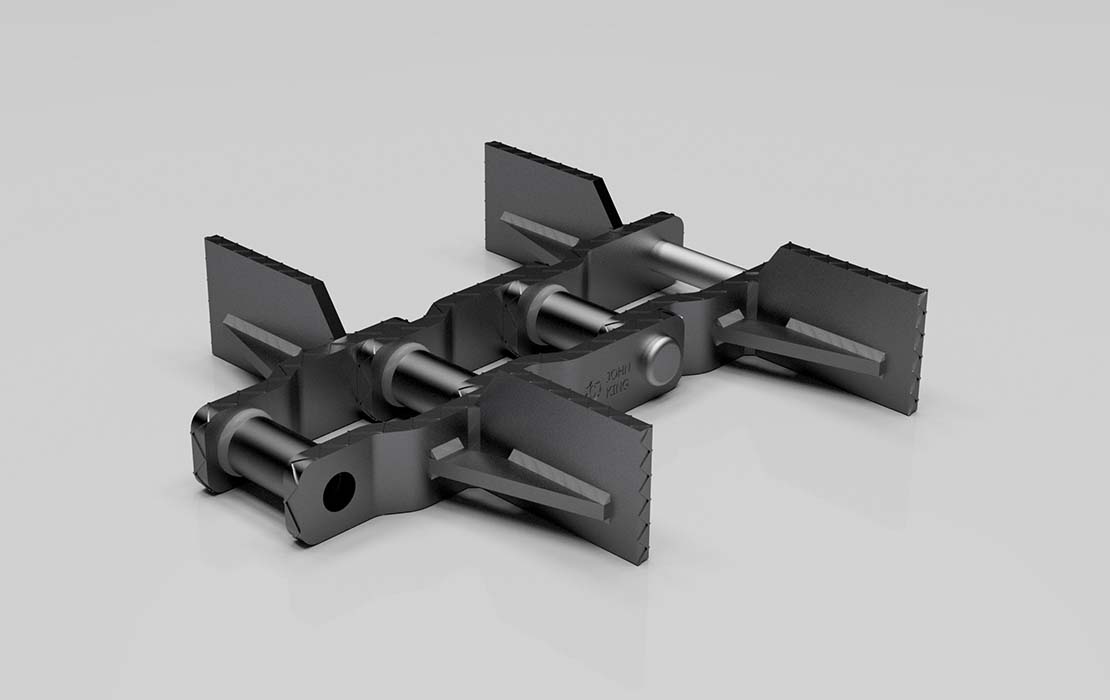

Crusader Heavy Duty Steel Drag Chains (WHX)

Have questions or need a quote?

Get in touch with the team today.

This welded steel option can be considered in place of cast S series drags and is ideal where conditions of high abrasion and heat prevail.

- Fabricated construction with material options in flat and round section for each component allows the construction of CRUSADER to have greater consistency and integrity.

- The CRUSADER Series employs optimum materials and heat treatment conditions to ensure good resistance to shock loading and extended service life. Square edged wing and link plate section creates increased conveying efficiency and transport of a deeper bed of material.

- Hard face welding on all sliding and wear surfaces is standard. A typical weld surface of 60 HRC and with heavy weld bead gives CRUSADER excellent sliding wear resistance in cold and hot clinker applications.

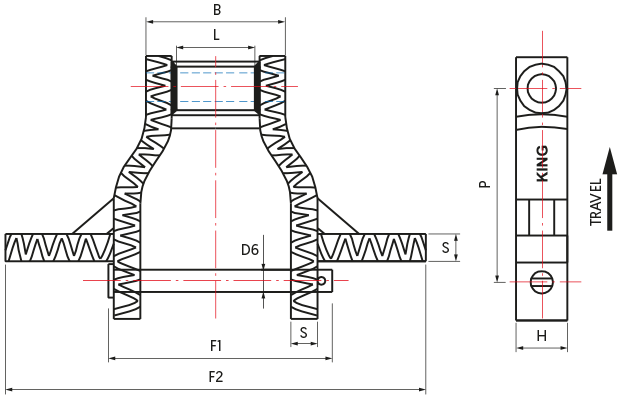

|

Crusader Heavy Duty Welded Steel Drag Chains |

||||||||||

|

Chain |

Pitch |

Rivets |

Over-All |

Width |

Between Sidebars |

Length |

Sidebars |

Average |

Average Weight |

|

|

Diameter |

Thickness |

Height |

||||||||

|

P |

D6 |

F1 |

F2* |

L |

B |

S |

H |

|||

|

inches |

lbs |

lbs/ft |

||||||||

|

WHX5157 |

6.05 |

1.13 |

6.94 |

8 to 14 |

2.75 |

4.63 |

0.63 |

2.50 |

175,000 |

4.63 |

|

WHX6067 |

9.00 |

1.25 |

8.19 |

10 to 26 |

3.63 |

5.50 |

0.75 |

2.50 |

225,000 |

5.50 |

|

WHX5121 |

9.00 |

1.25 |

9.75 |

10 to 30 |

3.63 |

6.31 |

1.13 |

2.50 |

275,000 |

6.31 |

|

WHX6121 |

9.00 |

1.25 |

9.75 |

10 to 30 |

3.63 |

6.31 |

1.13 |

2.50 |

275,000 |

6.31 |

* In increments of 2”.

Note: Breaking loads based on standard specification. For elevated temperatures this specification may change and with it the breaking load. Please consult John King technical.

The types illustrated are typical but many other versions which are variations on those illustrated are available.