American Standard without Rollers

Have questions or need a quote?

Get in touch with the team today.

The smooth and stable flow of material through a process depends on the performance of the conveyor chain installed within the equipment. Bush class chains or steel knuckle chain are of the same construction as roller conveyor chain, but with the roller excluded. This series, with a reduced number of components, has proved to be particularly successful in high duty, high abrasion applications where lubrication is not possible. For many years KING steel bush chains have been proving performance in mill duty centrifugal discharge elevators within the more difficult applications encountered in the Cement Industry.

|

American Standard – Engineered Steel – without Rollers B29-12 |

|||||||||||||||

|

Chain Number |

Pitch |

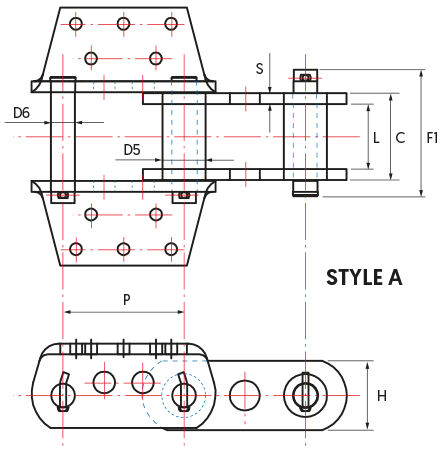

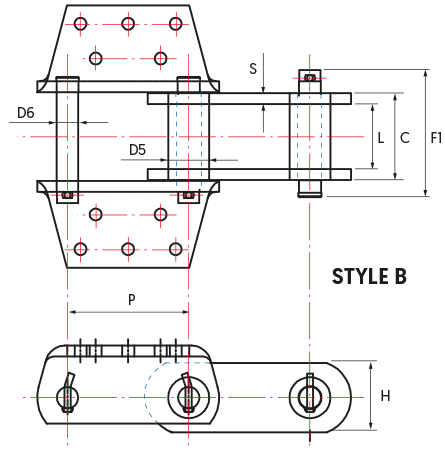

Style |

Bushings |

Pins |

Over-All Pin & Cotter |

Between Sidebars |

Sidebars |

Sprocket Number |

|||||||

|

Outside Diameter |

Width |

Heat Treat |

Diameter |

Heat Treat |

Thickness |

Height |

Heat Treat |

||||||||

|

D5 |

C |

D6 |

F1 |

L |

S |

H |

|||||||||

|

inches |

inches |

inches |

inches |

||||||||||||

|

JKB102B |

4.00 |

A |

1.00 |

2.89 |

CH |

0.63 |

CH |

4.37 |

2.13 |

0.38 |

1.50 |

TH |

102B |

||

|

JKB111 |

4.76 |

A |

1.44 |

3.39 |

CH |

0.75 |

CH |

4.97 |

2.63 |

0.38 |

2.00 |

TH |

111 |

||

|

JKB110 |

6.00 |

A |

1.25 |

2.89 |

CH |

0.63 |

CIH |

4.37 |

2.13 |

0.38 |

1.50 |

TH |

110 |

||

|

JKB856 |

6.00 |

B |

1.75 |

4.00 |

CH |

1.00 |

CIH |

6.44 |

3.00 |

0.50 |

2.50 |

TH |

856 |

||

|

JKB956 |

6.00 |

A |

1.75 |

4.00 |

CH |

1.00 |

CIH |

6.44 |

3.00 |

0.50 |

3.00 |

TH |

856 |

||

|

JKB857 |

6.00 |

B |

1.75 |

4.00 |

CH |

1.00 |

CIH |

6.44 |

3.00 |

0.50 |

3.25 |

TH |

856 |

||

|

JKB958 |

6.00 |

A |

2.00 |

4.13 |

CH |

1.13 |

CIH |

6.44 |

3.00 |

0.56 |

3.25 |

TH |

958 |

||

|

JKB859 |

6.00 |

B |

2.38 |

5.00 |

CH |

1.25 |

CIH |

7.74 |

3.75 |

0.62 |

4.00 |

TH |

859 |

||

|

JKB864 |

7.00 |

B |

2.38 |

5.00 |

CH |

1.25 |

CIH |

7.74 |

3.75 |

0.62 |

4.00 |

TH |

864 |

||

|

JKB984 |

7.00 |

A |

2.50 |

5.00 |

CH |

1.38 |

CIH |

7.74 |

3.75 |

0.62 |

4.00 |

TH |

984 |

||

|

JKB1084 |

7.00 |

C |

2.85 |

6.00 |

CH |

1.62 |

CIH |

8.60 |

4.43 |

0.75 |

4.50 |

TH |

1084 |

||

TH: Thru-hardened, CIH: Circumferential Induction Hardened after thru-hardening, CARB: Carburized SIH: Selectively Induction Hardened.

Key features of a World class product.

Pins manufactured from a high alloy steel to BS970 709M40 (AISI 4140) initially hardened and tempered to average 40Hrc in the core to give this tension component high tensile strength and toughness. Thereafter the pin is selectively induction hardened to create an armour plating to 58- 62Hrc at typically 10% of the diameter.

Bushings are produced from a high alloy carburising steel to BS970 805M20 (AISI 8620) subject to deep case carburising on all wearing surfaces both internal and external. An extended exposure to the carbon rich atmosphere of the furnace ensures that the best combination of high hardness (58-62Hrc) and maximised case depth is achieved.

Sidebars are uniquely uprated from traditionally carbon steels to alloy steel to BS970 530M40 (AISI 5140) These are supplied in a hardened and tempered condition average 40Hrc to offer increased tensile strength as compared to alternatives.

Although of fundamental importance Quality is not exclusively about materials and heat treatment. Controlled high interference fits are employed in relation to pins and bushings and relative side plates. By pre-stressing the sidebar pitch holes the fatigue life of the chain is extended.

The chains are produced within the dictates of the Company’s management quality system ISO9000 to ensure a high and consistent quality standard.