The undisputed Kings of laser profiling and fabrication

Have questions or need a quote?

Get in touch with the team today.

From survey to drawing to production – the one stop shop

John King Laser was established in 2007 primarily to service the mechanical handling division. It was well understood that the available capacity surpassed that of in-house requirements and the business model from the outset was to sell laser cut and fabricated parts to customers producing a wide range of machinery and equipment.

More recently the division has been able to support John King’s site service division where bespoke fabrications have been required. A good recent example would be the survey, technical drawing, production and installation of major fabricated structures within a EFW plant (Energy from waste).

The laser division has remained autonomous from the start whilst critically benefitting as part of a Group structure in investing in new technology to give the division a distinct advantage in efficiency and quality of products produced. The recent installation of the newest and probably best laser capacity in the country is testament to this.

Manufacturing capabilities

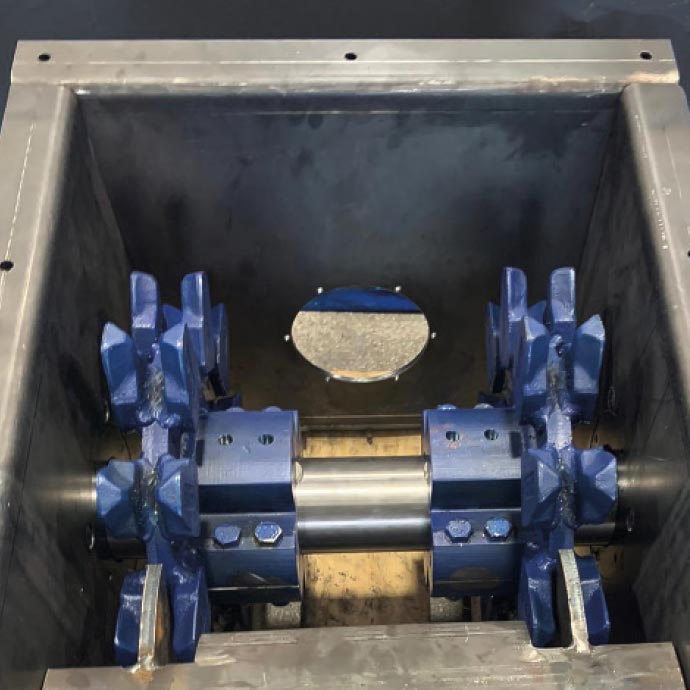

The 2020s business is a lean enterprise working from a modern manufacturing facility employing best production techniques including Fibre laser technology, plasma for thicker material sections, CNC machining and Robotics. Group structure provides the internal resource to implement production management systems that ensures highest quality, consistent and competitive products produced in a safe environment. All manufacturing is conducted within the dictates of ISO9000 to the latest 2015 standard to ensure quality objectives are monitored and maintained.

LASER CUTTING FACILITIES

- Mild and Carbon steel up to 25 mm.

- Stainless steel up to 15 mm.

- Aluminium up to 12 mm.

FLAME CUTTING AND PLASMA CUTTING FACILITIES

- Machine bed size of 8 m x 2.5 m.

- Flame Cutting up to 110 mm.

- Plasma Cutting up to 30 mm.

Press technology

In support of our impressive range of flatbed processing capabilities we operate CNC Synchro press brake machines capable of pressing parts with capacities up to and including 220 tons and 4000 mm in length, with smaller machines with 2000 mm gap and 100 mm stroke for smaller parts in higher volume production.

Welding and Fabrication

Our Welding and Fabrication capacity includes a high level of skill in both internal and external projects. This enables John King’s laser and fabrication division to offer an all-encompassing manufacturing service to Biomass and EFW plants. The site service division will thereafter take charge of the installation.