King BulkMaster Conveying

Have questions or need a quote?

Get in touch with the team today.

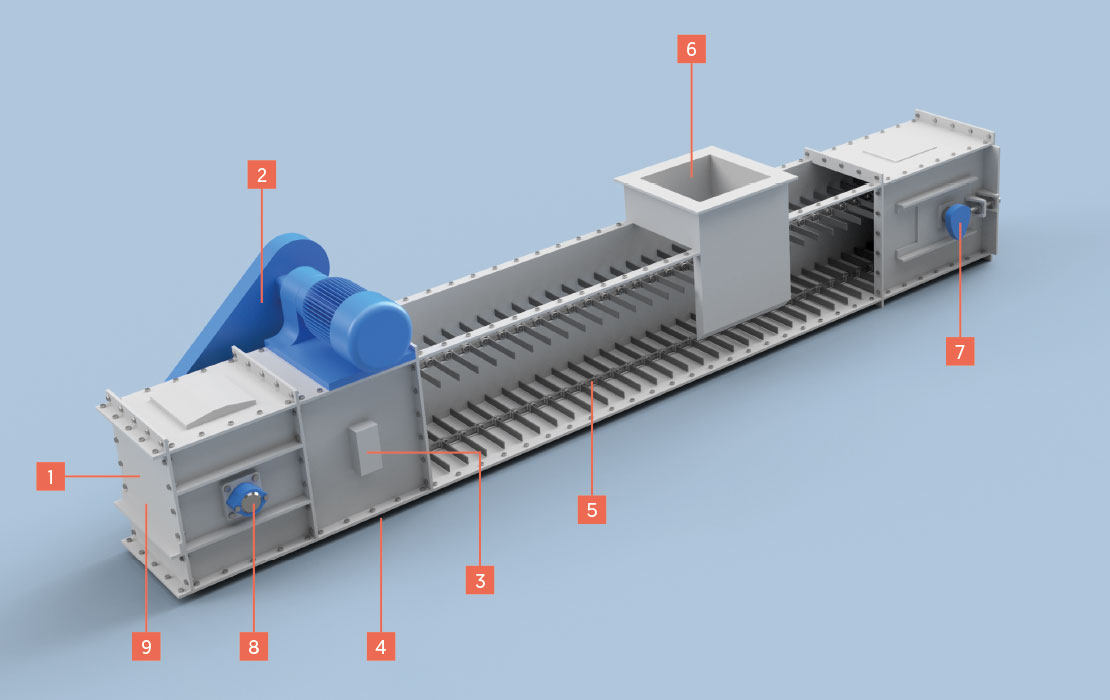

King BulkMaster machines employ the principal of en masse conveying. The chain flight will induce movement to its own physical depth and as a result the whole mass of material will flow forward at the same speed in a solid, placid column ‘en masse’. Material dragging, particle tumbling or rolling does not occur.

King BulkMaster machines are manufactured within a standard range from 200 mm wide to 1500 mm wide with capacities of up to 2000 tons per hour (grain). All requirements can be catered for.

- Multiple inlets and or outlets will provide proportional capacity intake and output.

- BulkMaster two way machines will allow for material transport in both directions.

- Totally enclosed casing.

- Integral or independently mounted drives.

- Safety choke detector.

- Single or Multiple outlets.

- King high strength forged conveyor chain.

- Single or multiple inlets.

- Underspeed safety control unit.

- Rotation sensor (optional).

- Blockage sensor (optional).

Popular BulkMaster Conveyor arrangements

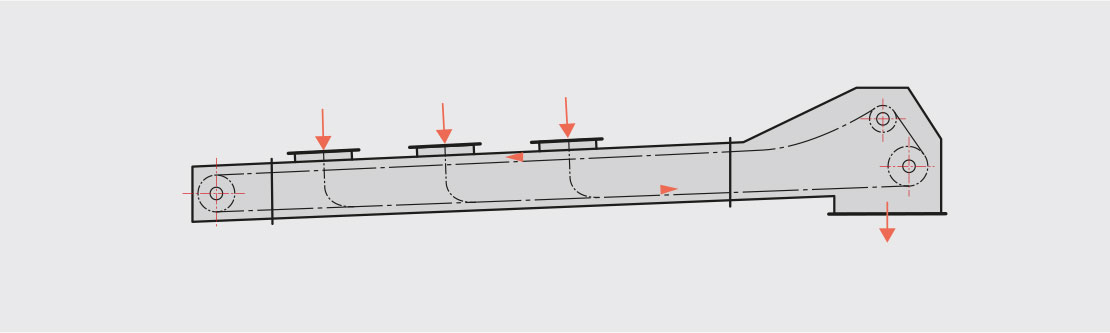

A. Standard straight running conveyor. Tensioning at the drive end as illustated or option of conventional tail shaft tensioning.

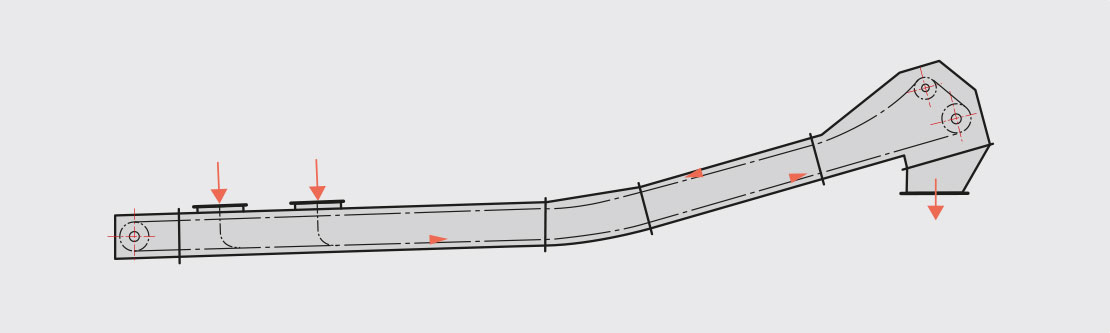

B. Standard straight running conveyor with horizontal to inclined sections. Tensioning at the drive end or option of conventional tail shaft tensioning.

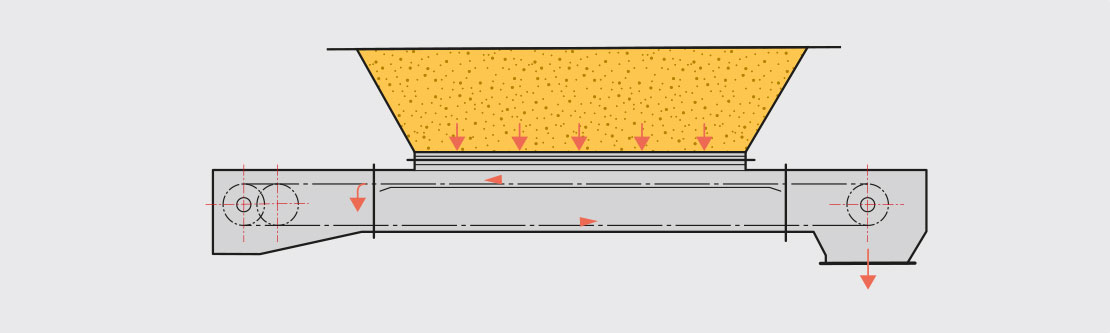

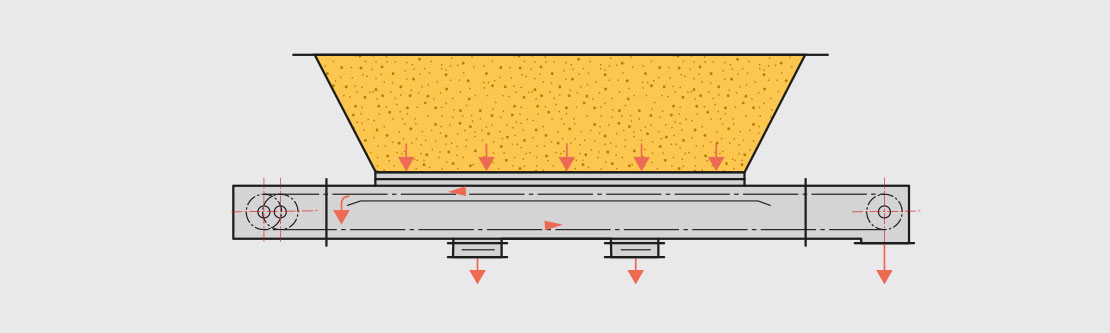

C. Two way conveyor with material delivery from a single hopper. Material conveyed on a closed top deck to enable delivery to the bottom strand in a controlled manner. Single outlet at drive end. Conventional tail shaft tensioning as illustrated or option of tensioning at drive end.

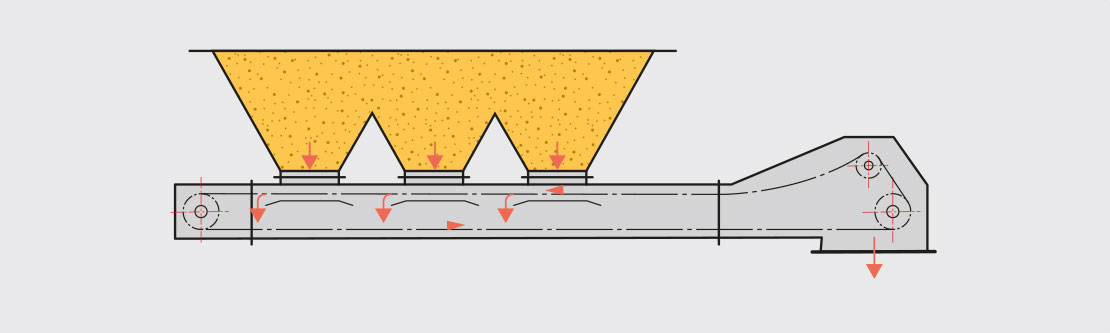

D. Standard straight running conveyor with delivery from multiple inlets directly to the bottom strand. Baffle plates allow for controlled feed. Single outlet at drive end. Tensioning at the drive end as illustrated or option of conventional tail shaft tensioning.

E. Two way conveyor with material delivery from a single hopper. Material conveyed on a closed top deck to enable delivery to the bottom strand in a controlled manner. Multiple outlets along conveyor length Conventional tail shaft tensioning as illustrated or option of tensioning at drive end.

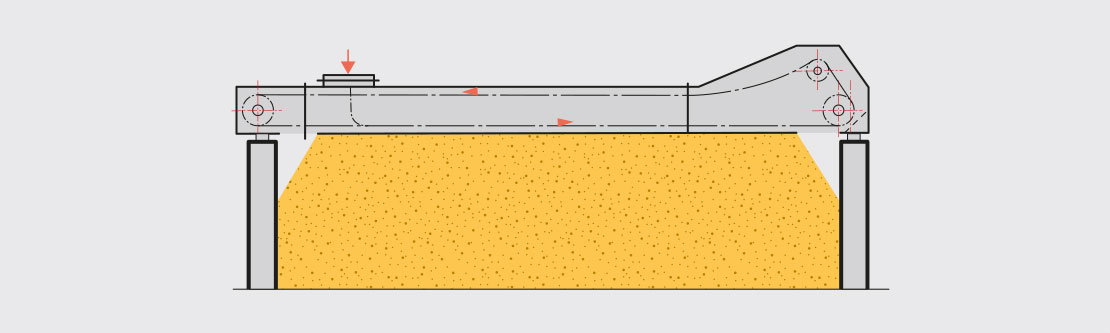

F. Horizontal conveyor with open bottom deck for material leveling. Tensioning at the drive end as illustrated or option of conventional tail shaft tensioning.