Problem-solving at a UK cement plant – article in the Global Cement Magazine

Have questions or need a quote?

Get in touch with the team today.

Problem-solving at a UK cement plant – article in the Global Cement Magazine

John King Chains Ltd is one of the most long-established chain producers worldwide. Originally a designer and manufacturer of mechanical handling equipment to the principal industries of mining, cement and steel, since the 1990s the business has focused on the manufacture of heavy and special series conveyor chains. John King’s tradition was in the manufacture of cast link chains in irons and steels and although cast link chains remain an important part of the programme, the company additionally produces engineering class, welded steel and forged fork link chain. This allows John King to offer the widest product range of any manufacturer.

Its tradition in manufacture of chain conveyors and elevators allows John King a unique insight into the design and selection of the ‘running gear.’ Its ability to select the correct chains for the application, up-rate existing chains to enhance performance and service reliability and assist in problem solving is an essential element to the service provided. This added value has been well received in the market and has allowed John King to form strong alliances with cement producers around the world.

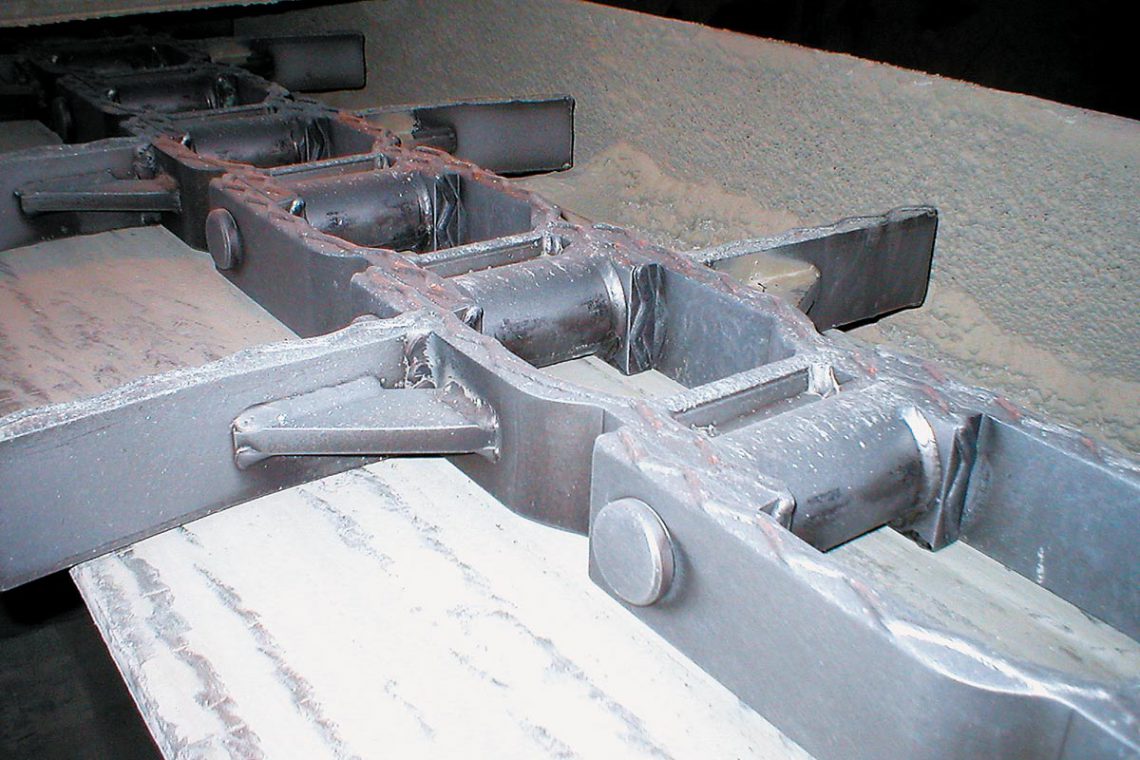

A good example of this can be seen in the John King Crusader range of high capacity drag chains. This welded steel option was developed as an alternative to the traditional cast manganese drag links encountered in many cement clinker drag conveyors. It is noted that all types of cast drag link chains encountered in Europe, North America and elsewhere typically including JKT, JKD, SD and JKS types can be converted to Crusader. This has proven to be ideal in areas where abrasion and heat prevail.

Of fabricated construction this chain follows the same format as John King welded steel chain with crank link profile and circumferentially welded bush. The Crusader series employs optimum materials and heat treatment to ensure good resistance to shock loading and extended service life. The plates are from an alloy steel with through hardening. The pin and bush are again direct-hardening alloy steels through hardened, the chain pin is additionally subject to secondary surface induction hardening to provide it with both a high core strength and a surface armour plating for wear resisatnce. Square-edged wing and link plate combined with ‘plough’ style dredging edge ensure increased conveying efficiency and transport of a deeper bed of material.

The key to its exceptional wear performance is through the addition of a matrix of hard facing on all wearing surfaces. Typical hardness values of 60Hrc are realised and with heavy weld bead gives Crusader excellent sliding wear resistance in hot and cold clinker applications.

Case study – Lafarge Hope Works, UK

The first conversion was carried out at a UK cement plant and the experience speaks for itself. Lafarge Cement Hope Works operates a clinker transport conveyor to deliver clinker to a main store. The casing size is 800mm with chain centres of 40m. This conveyor has a design capacity of 200t/hr. Originally the system employed a double strand forged chain with flight at every pitch point. The abrasive nature of the Hope clinker saw high wear rates to the assembly and the necessity for regular replacement and ongoing maintenance. This was considered inadequate and uneconomical.

“John King Chains approached me with a view to presenting an alternative,” explains Trevor Shaw, Mechanical Engineer at Hope Works. “Their proposal was a radical departure from the current system in being single strand. The design in its simple and robust construction was exactly what I considered was needed. This chain has given me six years of reliable performance in a very challenging application.”