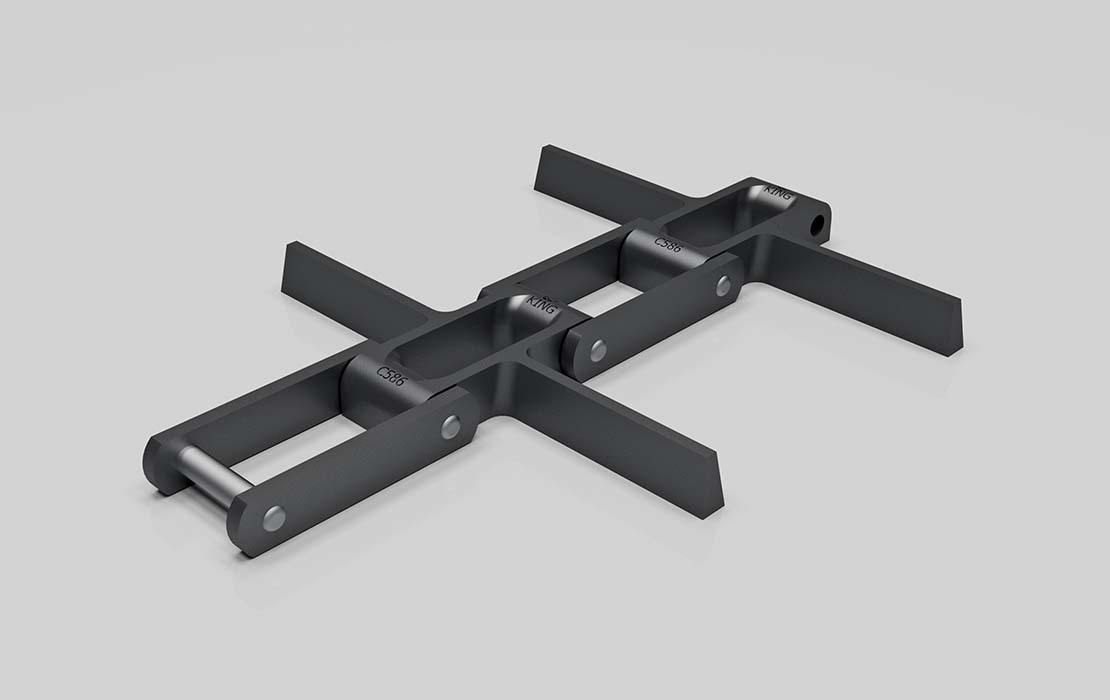

Cast Combination Trough Scraper Chains

Have questions or need a quote?

Get in touch with the team today.

John King have been the principal producer of cast combination chains for many years. This includes the flighted version typically employed in grain conveyors with a cast integral flight. Their experience is essential in material selection which combines strength and wear resistance as well as ductility. An additional version is available on C664 and C762 where an injection moulded plastic flight is riveted to the outer link. For corrosion resistance chains can be produced with stainless steel pins, a typical example being green malt conveying.

|

Cast Combination Trough Scraper Chains |

||||||||||

|

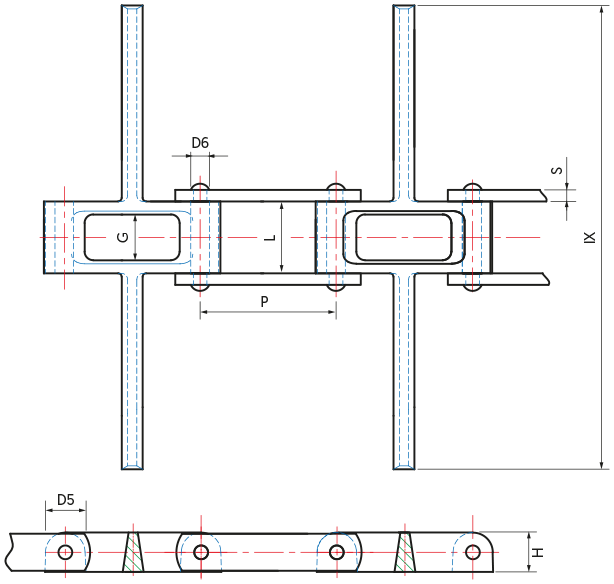

Chain |

Pitch |

Barrel |

Pin |

Between Sidebars |

Gearing |

Sidebars |

Overall Width |

Working Load |

Average Weight |

|

|

Outside Diameter |

Diameter |

Thickness |

Height |

|||||||

|

P |

D5 |

D6 |

L |

G |

S |

H |

IX |

|||

|

mm |

lbs |

kg/m |

||||||||

|

C586/T2X5 |

58.6 |

17 |

8 |

32 |

20 |

5 |

16 |

124 |

6,000 |

2.89 |

|

C586/T2X8 |

58.6 |

17 |

8 |

32 |

20 |

5 |

16 |

200 |

6,000 |

3.37 |

|

C586/T4X8 |

58.6 |

17 |

8 |

32 |

20 |

5 |

16 |

200 |

6,000 |

2.87 |

|

C664/T2X8 |

66.4 |

23 |

11 |

37 |

25 |

5 |

20 |

200 |

12,000 |

5.24 |

|

C664/P2X8 * |

66.4 |

23 |

8 |

37 |

20 |

5 |

16 |

200 |

12,000 |

3.89 |

|

C664/T2X9 |

66.4 |

23 |

11 |

37 |

25 |

5 |

20 |

220 |

12,000 |

5.90 |

|

C762/T2X12 |

76.2 |

32 |

14 |

43 |

26 |

6 |

30 |

290 |

24,000 |

10.86 |

|

C762/P2X12 * |

76.2 |

32 |

14 |

43 |

26 |

6 |

30 |

290 |

24,000 |

7.86 |

|

C762/T2X15 |

76.2 |

32 |

14 |

55 |

35 |

6 |

30 |

370 |

24,000 |

11.80 |

NR – Noise Reduction feature with deep link plate.

* P – Moulded engineering plastic flight riveted to outer link in place of cast flight. Available on C664 and C762.