Reverse Barrel Wide Series Drag Chains

Have questions or need a quote?

Get in touch with the team today.

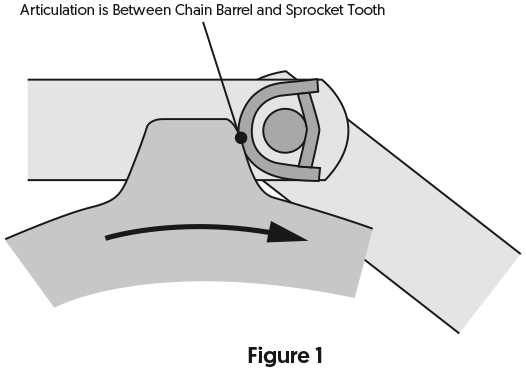

The standard wide series welded steel drag chain is designed to travel narrow end forward. In considering the offset sidebar style this direction of travel will create additional friction between the gearing face of the barrel and the tooth flank of the driving sprocket (fig.1). This condition is accentuated on short, centred conveyors where the frequency of barrel and sprocket interaction is increased.

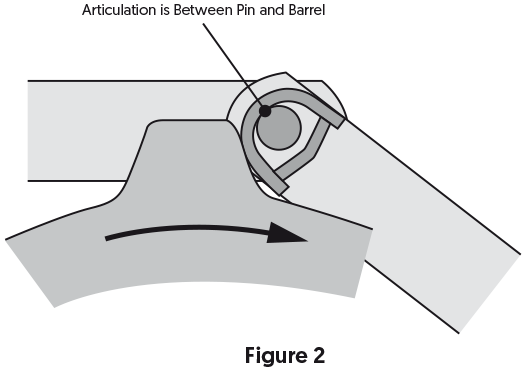

A simple solution was seen in the introduction of the RB series where the barrel is reversed to allow the chain to run open end forward. In this event instead of the articulation occurring between the barrel and tooth flank it occurs inside the internal area where the pin will rotate within the barrel (fig. 2). This is preferable since the components are specifically suited to contact between two hardened bearing surfaces along the entire width of the chain.

We therefore recommend RB series when centers are short and loads heavy where the typical failure mode is breaking chain barrels or welds.

|

Reverse Barrel Wide Series Drag Chains |

|||||||||

|

Chain |

Pitch |

Rivets |

Over-All |

Between |

Length |

Sidebars |

Breaking |

Average |

|

|

Diameter |

Thickness |

Height |

|||||||

|

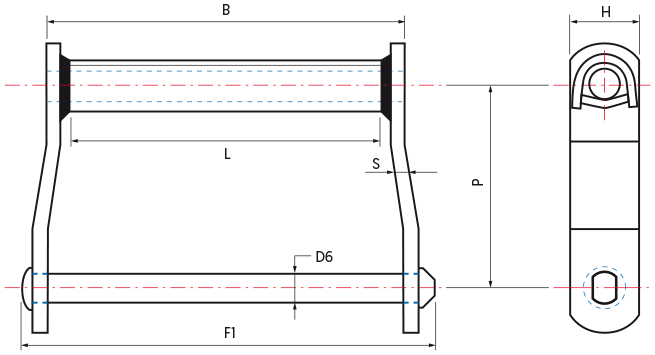

P |

D6 |

F1 |

L |

B |

S |

H |

|||

|

inches |

lbs |

lbs/ft |

|||||||

|

WDH110/RB |

6.13 |

0.75 |

11.75 |

9.00 |

10.25 |

0.38 |

1.50 |

55,000 |

12.00 |

|

WDH480/RB |

8.16 |

0.88 |

14.75 |

11.00 |

12.75 |

0.50 |

2.00 |

105,000 |

18.00 |

|

WDH580/RB |

8.00 |

1.00 |

14.75 |

11.00 |

12.75 |

0.50 |

2.00 |

140,000 |

19.40 |

|

WDH680/RB |

8.00 |

1.00 |

15.25 |

11.00 |

13.00 |

0.63 |

2.00 |

140,000 |

21.00 |